-

Key Takeaways

-

Understanding Aircraft Aging

- What Makes an Airplane "Old"?

- Old Airplanes: Myths vs. Reality

-

Factors Affecting Aircraft Safety

- Aircraft Maintenance and Inspections

- Metal Fatigue and Structural Integrity

- Corrosion and Environmental Exposure

- Upgrades and Modernization

-

Regulatory Requirements for Older Aircraft

- FAA Maintenance Regulations

- Aging Aircraft Inspections

- Record-Keeping and Documentation

-

Case Studies

- Successful Operation of Vintage Aircraft

- Notable Incidents and Lessons Learned

-

Benefits and Drawbacks of Flying Old Airplanes

- Advantages

- Challenges

-

Assessing the Safety of an Old Airplane

- Pre-Purchase Considerations

- Ongoing Maintenance Practices

- Pilot Training and Familiarity

-

FAQs

-

Conclusion

Some pilots have checked their aircraft’s documentation, only to find that it was manufactured in the 1980s, and feel their stomachs drop.

If you’ve ever flown one of these airplanes, you too might have felt a sense of unease. But is there really cause for suspicion?

Don’t worry, just yet. Let’s examine this myth and see where the concern comes from. And after looking at the facts, you can objectively decide whether the myths actually hold up.

Key Takeaways

- Aircraft age alone is not a direct and inherent safety hazard.

- Timely inspections, proper upkeep, and fatigue control keep older aircraft airworthy.

- Older aircraft are affordable and reliable, but may need more maintenance and parts sourcing.

- Before buying an older aircraft, it must be thoroughly inspected and have complete records.

Understanding Aircraft Aging

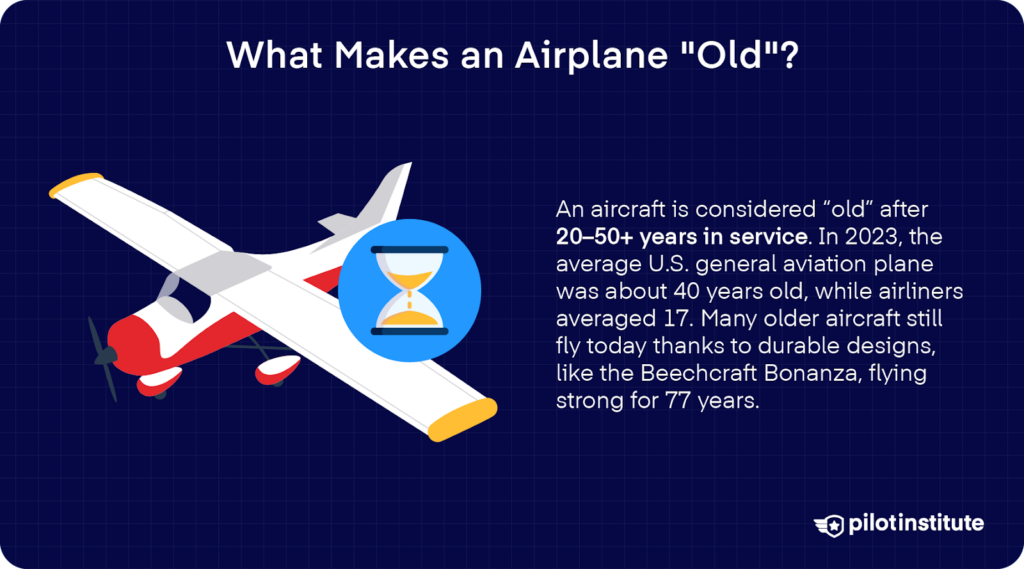

What Makes an Airplane “Old”?

An airplane is generally considered “old” when it’s been in service for 20, 30, or even 50+ years. If your aircraft has been flying since the 2000s or earlier, then yes, it is old.

But with that said, “true aging” really depends on its design standards and how it’s used. In fact, many general aviation models were designed under 1950s-era Civil Air Regulations and remain in active service today.

How old is the average aircraft? FAA statistics from 2023 found that the average age of U.S. general aviation airplanes was around 40 years. In contrast, commercial airline aircraft tend to be much younger, only around 17 years on average.

But even though they were made decades ago, many airplanes still fly today because they were designed with wear and tear in mind.

For example, the Beechcraft Bonanza has been around for 77 years with over 18,000 units built. This is the longest continuously produced GA airplane.

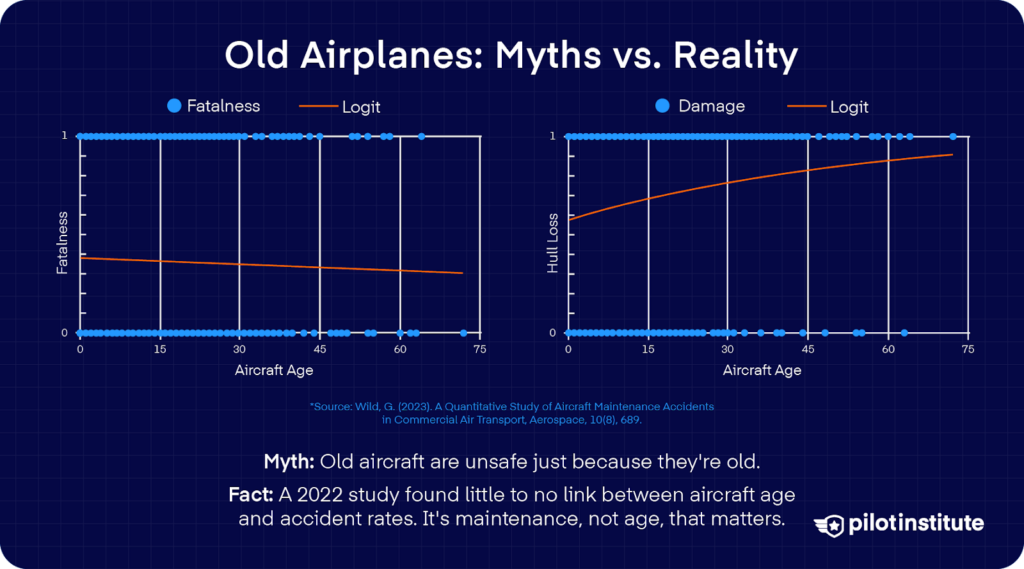

Old Airplanes: Myths vs. Reality

But now, let’s talk about some of the myths surrounding aging aircraft.

A big one is that old aircraft are unsafe purely because of their age. Their avionics are outdated and incompatible with modern technology. Worse, a wing could just snap off at any given moment. You might even compare flying an old aircraft to driving a clunker on the highway.

Sound familiar? Let’s investigate.

When you look at it objectively, age by itself doesn’t cause accidents. A 2022 study found that there is practically no correlation between aircraft age and accident rate.

In reality, structural failures typically result from poor maintenance or missed inspections. So, how can you make sure that your aging aircraft are always safe?

If you’re in GA, the FAA’s got you covered with its roadmap for aging airplane programs. This talks about risk identification and maintenance guides for aging aircraft, in particular.

And if you think aging aircraft can’t keep up with modern technology, that assumption might not fly. Even if you have a classic Cessna 172 or a Beechcraft Bonanza, your aircraft can now be retrofitted with Garmin’s G1000 NXi integrated flight deck.

From vintage avionics, you get features like wireless database updates and live weather and traffic overlays, all while using the same panel footprint.

Factors Affecting Aircraft Safety

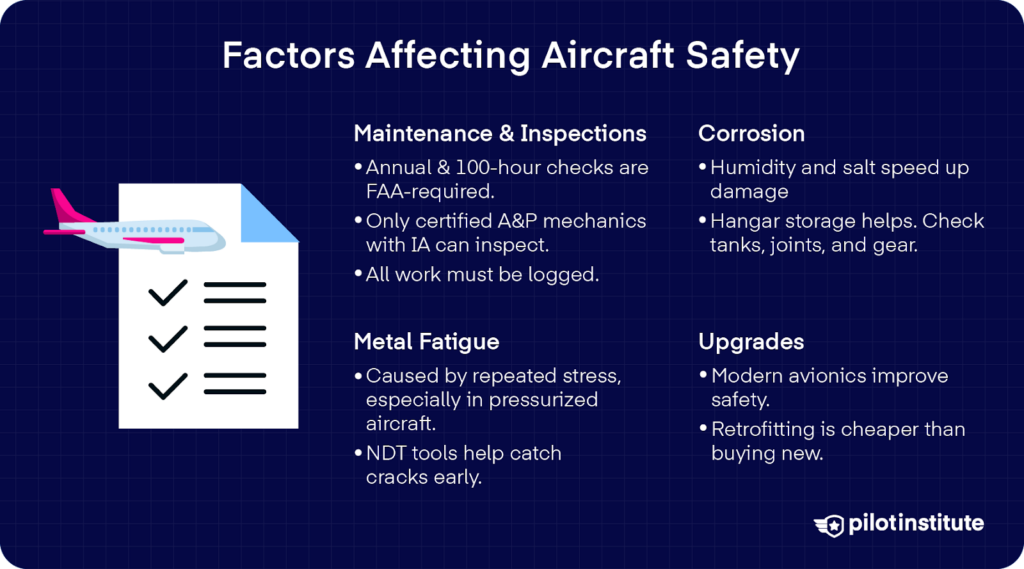

Aircraft Maintenance and Inspections

Unlike cars which are usually only brought to the shop when something goes wrong, civil aviation regulations require all U.S. aircraft to undergo inspection every year. If you fly an aircraft carrying passengers for hire, it’ll also need a 100‑hour inspection every 100 flight hours.

Yes, the aviation industry is that strict about safety.

The owner or operator is responsible for keeping the aircraft airworthy. They must either personally oversee these inspections or ensure they are done according to the FAA’s standards.

Routine inspections are designed to spot corrosion or other emerging issues before they can even become a threat.

Who can do these inspections? Not just anyone; inspections have to be conducted by qualified mechanics like A&P mechanics who hold Inspection Authorization.

They perform the inspections according to approved procedures. And after every repair, preventive maintenance, and inspection, it needs to be recorded in a detailed log.

Metal Fatigue and Structural Integrity

You’re right to think that the metal components in your aircraft wear down over time. But to be specific, metal fatigue arises from repeated stress cycles rather than calendar age.

If you fly a pressurized aircraft, it’s especially prone to cyclic stress from pressurization and depressurization. This can make small cracks in the fuselage or critical joints.

How can you spot fatigue early? Non-destructive testing (NDT) techniques like ultrasonic, eddy-current, and dye penetrant are great ways to identify the extent of damage without having to scrap your airplane’s parts.

Corrosion and Environmental Exposure

People in the industry are well aware of the elements in the environment that can exacerbate aircraft damage.

Exposure to humidity, salt, and sharp temperature swings creates the perfect recipe for corrosion. If your aircraft is stored outdoors, it’ll be much more vulnerable than those kept in hangars.

But despite these dangers, you don’t have anything to worry about if you take the right steps given by the FAA. Keep your aircraft in a hangar whenever possible. It protects the airframe from the sun and corrosive pollutants, especially if you live in coastal or humid areas.

Which areas of your aircraft should you pay extra attention to? Keep a close eye on your fuel tanks, control surfaces, landing gear, and structural joints. Always check them for pitting and fretting corrosion.

Upgrades and Modernization

Older aircraft can be brought up to modern standards with today’s avionics like GPS navigation, glass cockpits, and more reliable autopilots. While they’re not required under Part 91, they do a lot to boost safety and give you better situational awareness.

Retrofitting can also help older aircraft keep up with newer safety and efficiency standards. Better tools in the cockpit can help reduce your workload in a busy airspace.

If you’re planning on buying a new aircraft, consider upgrading what you already have instead of buying something new. It’s often more affordable while giving you the benefits of modern tech, all in a familiar airframe.

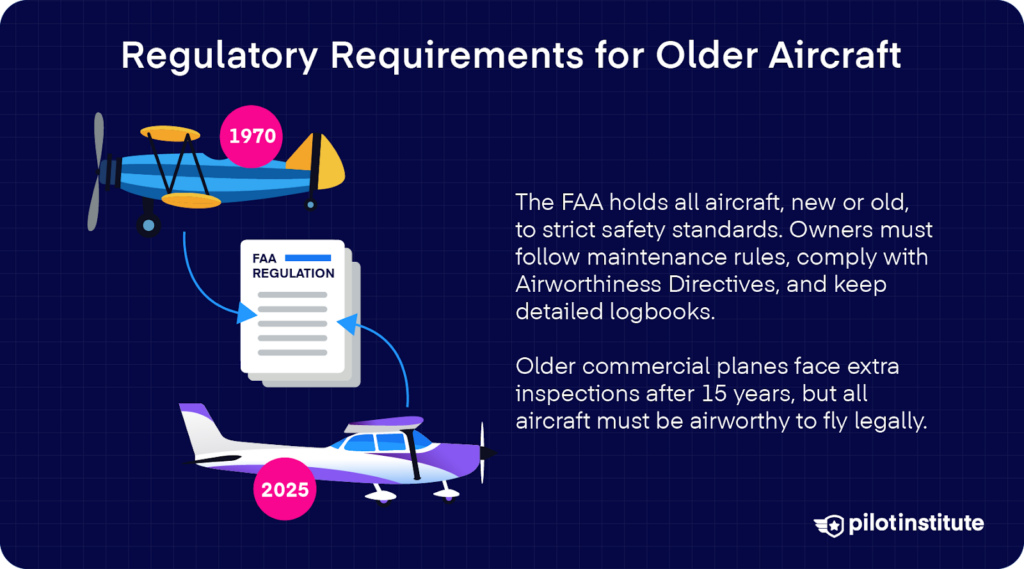

Regulatory Requirements for Older Aircraft

The FAA issues strict rules to ensure that all aircraft meet the same safety standards, no matter how old. So even if your airplane has been flying for decades, you can be confident it’s still being held to high regulatory oversight.

FAA Maintenance Regulations

All aircraft need to be maintained according to FAA rules to be considered airworthy. The law says you can’t legally operate any aircraft unless it’s in airworthy condition.

It’s the owner or operator who’s ultimately responsible for making sure the aircraft meets all safety and maintenance requirements. But for determining its airworthiness before every flight, that job is all on you.

That includes following every applicable Airworthiness Directive (or AD), which is why the FAA sends these notices directly to registered owners.

What are Airworthiness Directives? They’re legally binding instructions the FAA issues when it finds a safety issue that affects a certain type of aircraft, engine, or part.

Once published, aircraft owners are required to fix the issue within a certain timeframe. And if you ignore an AD, the aircraft is no longer legally airworthy.

Aging Aircraft Inspections

To keep older commercial aircraft flying safely, the FAA has a special rule called the Aging Airplane Safety Rule. Once certain types of aircraft reach their 15th year in service, they must go through extra inspections and a complete records review. These checks then repeat every seven years.

Who does this rule apply to? It’s mainly for commercial operations, as required in:

But even though private aircraft used under Parts 91 and 125 aren’t covered, you’ll still have to pass annual inspections and follow ADs.

On top of inspections, operators may need to update their maintenance programs or install newer parts to keep their aircraft aligned with current safety standards.

Record-Keeping and Documentation

Every aircraft has its own set of logbooks. It lists down all work done on the airframe, engine, and sometimes the propeller and other parts. You should see a detailed chronicle of every work done on your aircraft, all to make sure you’re flying safely.

Accurate records help prove that the aircraft is still safe and legal to fly. But aside from that, they’re also essential when you sell your aircraft or renew its insurance.

If you were a potential buyer, of course, you’d prefer an aircraft with clean, complete logs over one with missing or sloppy records. But worse than a sales problem, it’s illegal, and the aircraft could be grounded until things are sorted out.

Case Studies

As aviation matures, so have aircraft in the industry. Airplanes aren’t getting any younger, so the entire industry needed to work together to address the issues surrounding aircraft aging.

History has given us many lessons throughout this undertaking, both good and bad. But regardless, they’ve only taught us how to make flying safer moving forward.

Successful Operation of Vintage Aircraft

Did you know that some vintage aircraft are still fully operational today, decades after they first took flight? Take the Douglas DC-3, for example. Its design dates back to the 1930s, and it continues to fly in cargo services, sightseeing tours, and other specialty operations.

As of 2023, more than 150 of these sturdy workhorses remained in the air. These aircraft and others like the Mustangs, Spitfires, and B-17 bombers are actively flown by enthusiast groups and historical organizations.

Their secret? Comprehensive maintenance programs. What’s more, owners often work hand-in-hand with parts specialists and certified repair stations.

At facilities like The Warbird Factory, FAA-certified mechanics with specific experience in warbirds do the inspections and repairs. So yes, aircraft can stay as authentic and true to their design as possible without compromising flight safety.

Notable Incidents and Lessons Learned

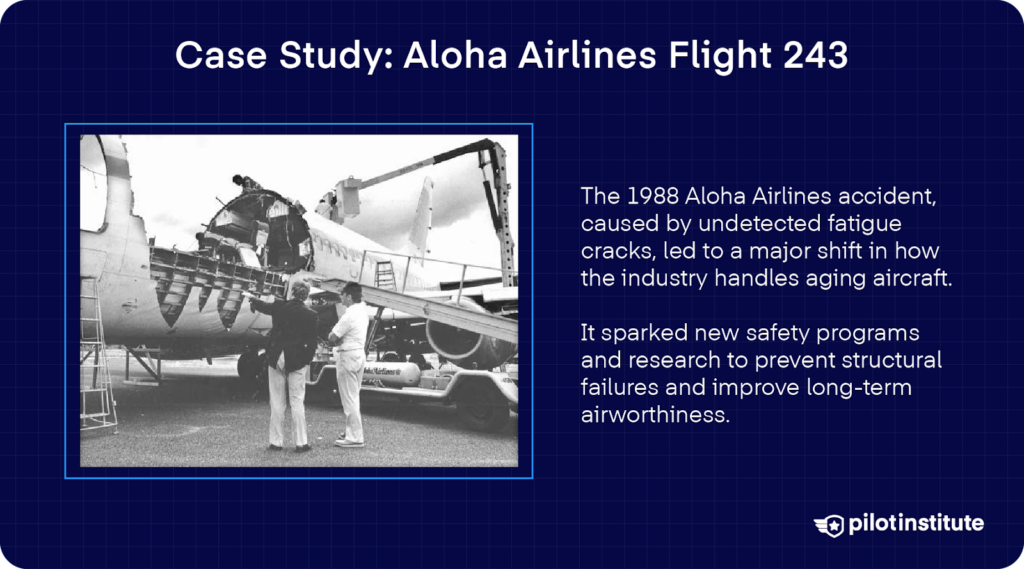

The tragic part, though, is that ageing aircraft wouldn’t have been this safe today if not partly due to some hard lessons along the way.

One of the biggest aging-related accidents was Aloha Airlines Flight 243 in 1988. The Boeing had flown nearly ninety thousand pressurization cycles, with each landing slowly stressing the airframe.

During cruise flight, an 18-foot section of the fuselage’s upper structure suddenly ripped away, which caused explosive decompression. Tragically, a flight attendant was lost overboard.

But how does a fuselage section just get torn from an aircraft? The NTSB determined that the airline’s failure to detect fatigue cracks in the aircraft was the cause. Made worse by its exposure to salt and humidity, it ended up in structural failure.

This accident shook the industry, and it became a catalyst for the creation of several programs for aging aircraft. It prompted the FAA, airlines, and aircraft manufacturers to work together on aging aircraft research, where issues like Widespread Fatigue Damage (WFD) were identified and addressed.

Benefits and Drawbacks of Flying Old Airplanes

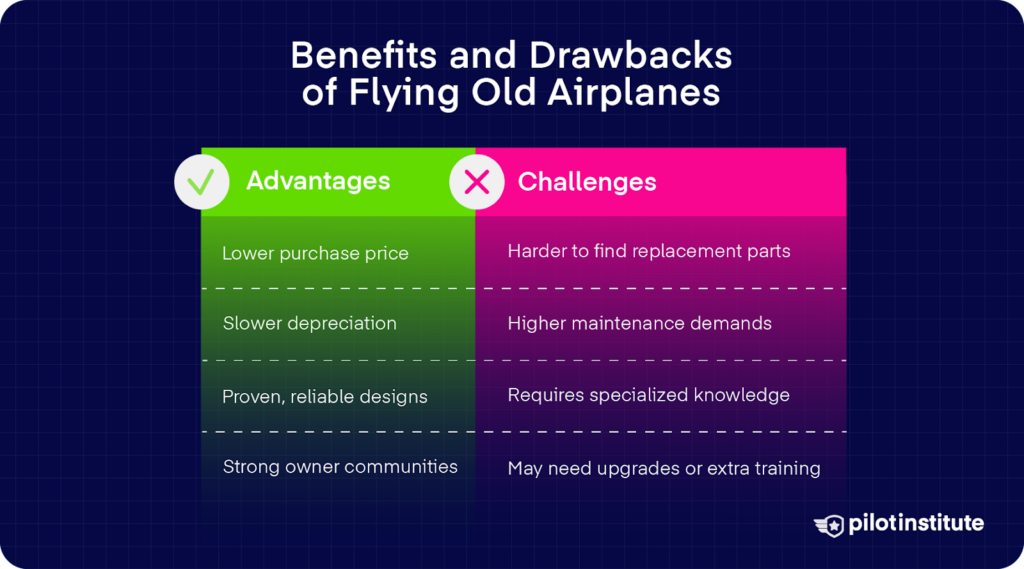

Are you thinking of purchasing an old aircraft of your own? Before deciding if they’re the right choice, you should first weigh their pros and cons.

Advantages

Cost-Effectiveness

One of the biggest reasons pilots choose older aircraft is their cost. Compared to new models, older airplanes are often far more affordable. You can buy a 1984 Cessna 172 for just under $200,000, and sometimes for even much less.

Another big plus about buying older aircraft is that they don’t depreciate as much. Since they’ve already gone through the steepest depreciation phase, their resale value tends to be more stable over time. This will be helpful if you ever decide to sell.

Proven Designs

On top of that, older aircraft also have tried and tested designs. These airframes and systems have been around for decades, so you already know how they behave.

Mechanics are familiar with inspecting and maintaining them, and there’s a wealth of operational experience to draw from. Maintenance procedures are well-documented, and there are even detailed inspection checklists specifically tailored to these models.

Community Support

One of the best things about having an older aircraft is the strong community support. Many aircraft types have dedicated owner groups and clubs where people share advice. Having a support network to lean on makes ownership responsibilities a whole lot easier.

These types of clubs often publish maintenance guides and offer technical support. Some of them even help connect owners with qualified mechanics. That kind of shared knowledge can make a big difference in keeping older aircraft both safe and affordable.

Challenges

Parts Availability

Of course, flying older aircraft doesn’t come without its challenges. For example, it can be a real challenge to find replacement parts.

If a manufacturer no longer makes them, your only options might be to look for used parts, have components custom-made, or hunt through salvage yards.

Maintenance Effort

Older aircraft also tend to need more attention. They may require more frequent inspections and occasional repairs simply because of age and wear.

Over time, this can add up to higher maintenance costs and longer downtimes. Some older models also need more in-depth checks than newer ones, especially if they’ve been flown a lot.

Specialized Knowledge

It’s also important to find the right mechanic. Not every technician is familiar with legacy aircraft systems. That means you might need to look for specialists or even learn more yourself.

Lastly, older airplanes sometimes come with outdated equipment or systems. If you’re used to a glass cockpit, you might need extra training to get comfortable using older systems. Even when newer avionics are installed, it’s still important to know how the original systems work.

Assessing the Safety of an Old Airplane

Pre-Purchase Considerations

So, you’ve decided to buy an older aircraft. But where do you start, and what criteria should you keep in mind?

First, enlist the help of an expert. A detailed pre‑purchase inspection by a qualified A&P mechanic is absolutely non-negotiable. And since we’re dealing with old aircraft, you should emphasize the need to inspect for any cracks, leaks, or corrosion.

You’ll also need to take a look at the maintenance history. If you spot any missing records or unexplained gaps, take that as a warning sign.

Finally, look at the total time and usage patterns, not just the calendar age. High-cycle aircraft used heavily for short flights are more likely to undergo fatigue stress than a similar-aged airplane used less frequently.

Ongoing Maintenance Practices

Once you own an older aircraft, you’ll need to have a proactive maintenance plan. That should include scheduling regular annual or 100-hour inspections, and adding in extra checks targeted at fatigue-sensitive areas.

It’s best to choose mechanics experienced with older types. Look for those familiar with vintage systems. Specialists can often spot subtle signs that general-service mechanics tend to miss.

Also, consider upgrading or replacing key components for an aging machine. Corrosion-resistant parts or modern NDT tools make you less likely to run into some nasty surprises down the line.

Pilot Training and Familiarity

The big question is, are you ready to handle an older aircraft?

Remember that older aircraft often tend to have handling quirks. It might have odd carburetor heat behavior or unique stall characteristics, or just entirely unfamiliar switches that you haven’t seen in newer types.

Instead of just flying to develop a “feel” of your aircraft, supplement this with type-focused seminars and training.

Type clubs and owner communities give you valuable support throughout this transition. They frequently host workshops and share model-specific insights. Your connections will give you access to hard-won advice, and maybe even informal mentorship.

FAQs

“Can older aircraft be as safe as new ones?”

Absolutely. The safety of an aircraft depends on maintenance, inspections, and proper upkeep—not how many years it has flown.

The issue is more correctly a function of fatigue exposure. Regardless of age, if the aircraft is protected from fatigue and environmental hazards and is regularly inspected, then it should meet the airworthiness standards set by the FAA for all aircraft.

“Are parts for older aircraft still available?”

Yes, though availability depends on the model. For many vintage aircraft, the FAA’s AC 23-27 now allows certified mechanics to use non-original parts for non-safety-critical components—without lengthy approvals—for aircraft under 12,500 lb.

For critical components like control surfaces and compressor blades, FAA-authorized PMA parts are available from approved manufacturers.

You’ll also find a lot of help from clubs and specialized shops when looking for parts. They can even fabricate replacements and help accomplish FAA acceptance paperwork like Form 337s.

“What should I consider before buying an older airplane?”

The process of buying an older aircraft can get overwhelming. But to keep you from getting lost in the details, let’s boil it down to three key criteria:

- Thorough inspection. Get a full pre-purchase inspection by an A&P mechanic who understands the specific aircraft and checks critical areas.

- Maintenance records. This is how you can tell whether an aircraft is well taken care of. As you study the logbook, keep an eye on inspections, AD compliance, and any maintenance gaps.

- Total hours and cycles. Beyond the age, check the total flight hours and number of flights. Time and again, it’s been proven that flight cycles (takeoffs/landings) often matter more than years when it comes to structural fatigue.

Conclusion

An aircraft’s age doesn’t determine its safety. What truly matters is how that aircraft has been maintained, inspected, and operated over time.

We’ve seen how well-maintained older aircraft can operate safely for decades. We’ve also seen where things go wrong when they’re neglected into a liability.

If you want consistent success, follow the inspection schedules and cooperate with experienced mechanics. As a pilot, you also need to understand the systems and quirks of your aircraft.

So if you’re considering flying or owning an older airplane, do it with respect for the machine, the life it’s lived, and the responsibilities it comes with.

Remember that being a part of aviation’s history of safety is a privilege. And if you do your part well, you’ll be helping preserve one of its greatest legacies.