-

Key Takeaways

-

What Is a Variable-Sweep Wing?

- Early Development

-

Why Use Variable-Sweep Wings?

- Swing Wings in the Military

-

How Do Swing Wings Work?

- Mechanical Systems

- Adjustment Methods

- Structural Considerations

-

Advantages of Variable-Sweep Wings

- Optimized Performance Across Speeds

- Improved Takeoff and Landing

- High-Speed Efficiency

- Enhanced Tactical Flexibility

-

Disadvantages of Variable-Sweep Wings

- Mechanical Complexity

- Added Weight and Maintenance

- Reduced Internal Space

- Aerodynamic Compromises

-

The Decline of Variable-Sweep Wings

- Stealth Requirements

- Cost and Maintenance Considerations

- Examples of Fixed-Wing Replacements

-

The Legacy and Future of Swing Wings

- Impact on Aviation History

- Current Use and Potential Future Applications

- Research into Variable Geometry

-

Conclusion

Aircraft that transform their wing shape mid-flight might sound like something out of a futuristic sci-fi, but they’re actually as old as the jet age itself.

Variable-sweep wings, or “swing wings,” revolutionized aircraft design by helping aircraft fly at their best in various flight conditions. They’re a symbol of an era of innovation that aimed to maximize performance across a wide speed range.

Let’s talk about one of the first experiments in modern aviation, how they work, why we don’t see them as much anymore, and how they shape the present and future of aircraft design.

Key Takeaways

- Variable-sweep wings adjust in flight to balance lift and speed.

- They improve takeoff, landing, and supersonic performance.

- The design adds weight, complexity, and maintenance needs.

- Modern jets favor simpler, stealthier fixed-wing designs.

What Is a Variable-Sweep Wing?

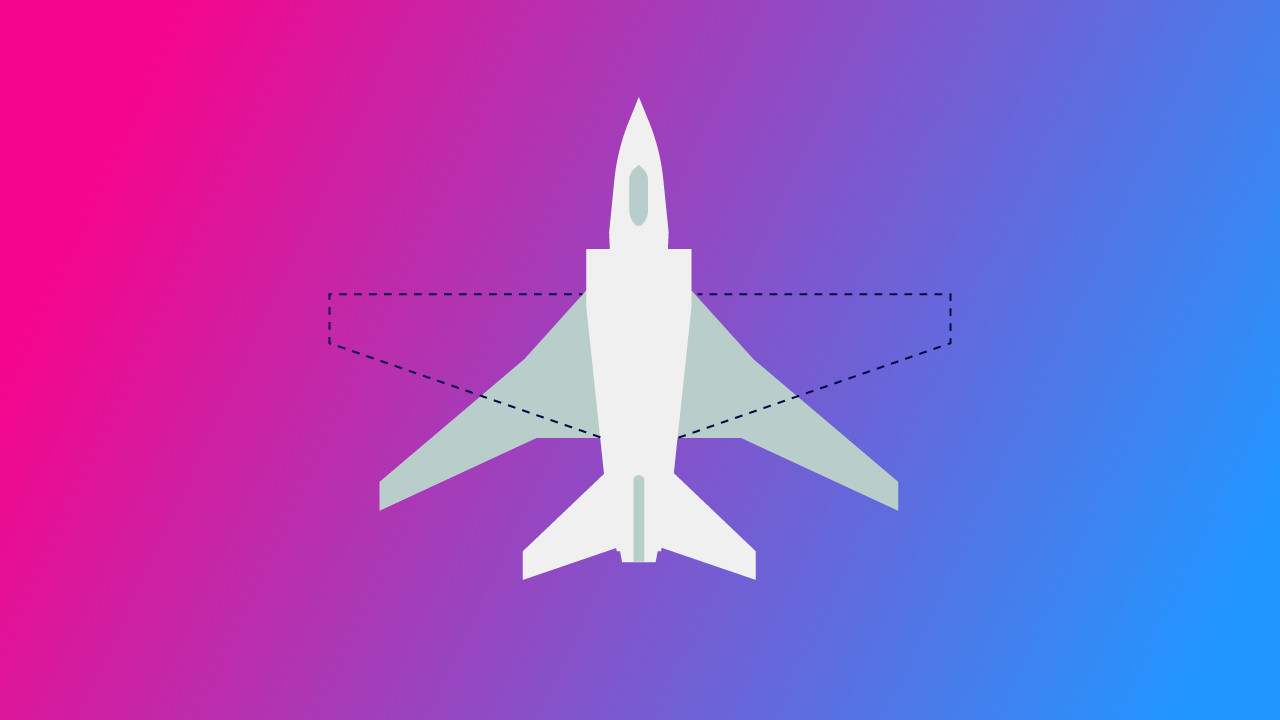

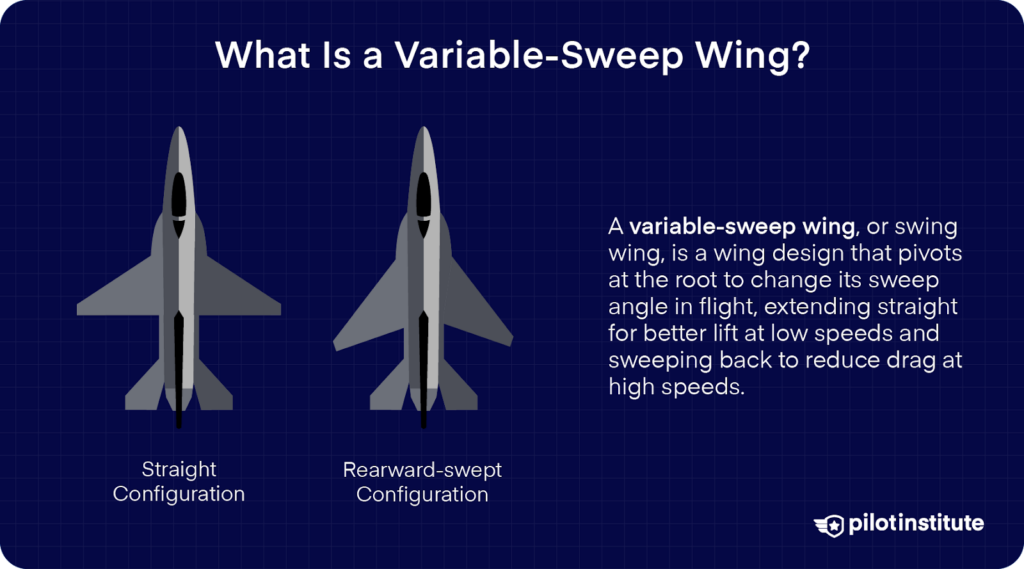

A variable-sweep wing, also called a “swing wing,” is a type of airplane wing that can change its angle while flying. The wings can be swept back or returned to a straight-out position, depending on which configuration is best for the phase of flight.

The wings pivot at hinge points near the fuselage to adjust the sweep angle. You can adjust them either manually or automatically, depending on your aircraft.

Early Development

How did it all start? Aviation in the 1940s and 1950s was facing its next challenge: transonic and supersonic flight. One of their answers to this problem was variable-sweep wings. German engineers started this innovation with the Messerschmitt P.1101.

This aircraft was an experimental jet fighter with wings that could be adjusted to different sweep angles on the ground. And although the P.1101 never flew, it laid the foundation for future developments.

In America, engineers developed the Bell X-5 in the early 1950s, which built upon the concept of the P.1101. This was the first aircraft capable of changing its wing sweep during flight.

Engineer Barnes Wallis from the U.K. explored variable-geometry aircraft through the Swallow project. His goal was to create aircraft that can fly efficiently across a range of speeds.

Even though the Swallow did not enter production, Wallis’s work had a massive impact on swing wing developments throughout the globe.

Why Use Variable-Sweep Wings?

Variable-sweep wings allow an aircraft to change the angle of its wings during flight. When you have this option, your aircraft can perform better at both low and high speeds.

How do they give you a boost in flight? To answer this, we need to discuss how different sweep configurations produce different aerodynamic effects.

Straight Wings and Swept Wings

At low speeds, like when you’re taking off or landing, you can extend the wings straight out to produce more lift. This is because straight wings have a higher aspect ratio, which also increases the coefficient of lift. As a result, your aircraft can stay in the air at slower speeds.

As you reach high speeds, especially near or above the speed of sound, you can then sweep the wings back to reduce drag.

But why are swept wings ideal for transonic and supersonic flight? They delay the formation of shock waves that cause wave drag. Because of this, your aircraft will be able to fly faster and more efficiently.

A variable-sweep wing essentially gives you the best of both worlds. You’ll be able to change the wing sweep angle during flight. It can adapt to different speeds and flight conditions.

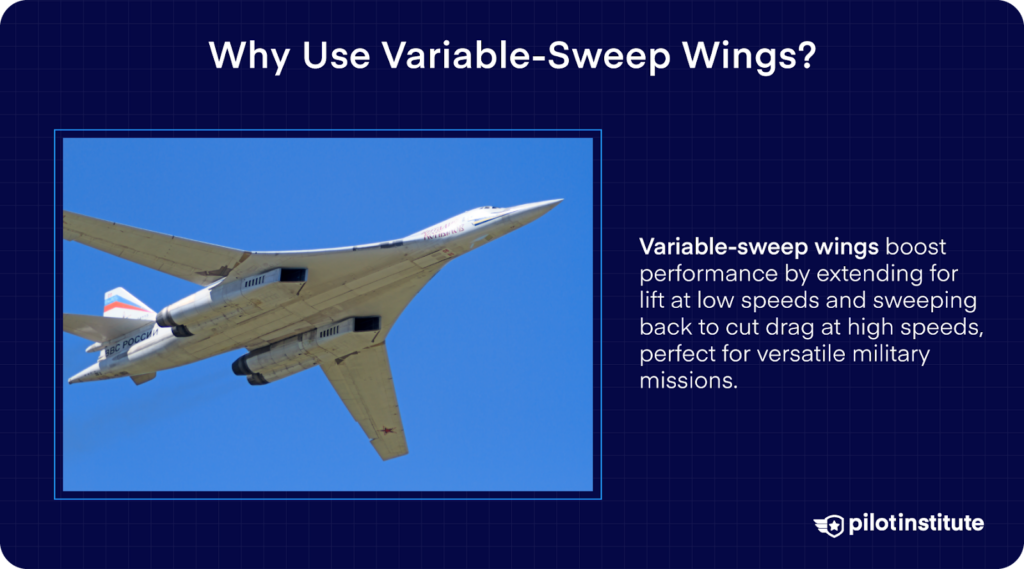

Swing Wings in the Military

This adaptability is essential in the military. Here, aircraft must perform well at both low and high speeds to handle different missions.

For example, military aircraft need to fly slowly for ground support and landings, but also to reach high speeds for interception and combat.

The Tornado IDS used its swing wings to fly slowly and save fuel while loitering at subsonic speeds. Then, when it was time to attack, it could quickly descend to treetop level for a high-speed strike.

You can probably see why the military had experimented with swing wings. They are very versatile, and they solved a lot of the problems they had with conventional aircraft.

How Do Swing Wings Work?

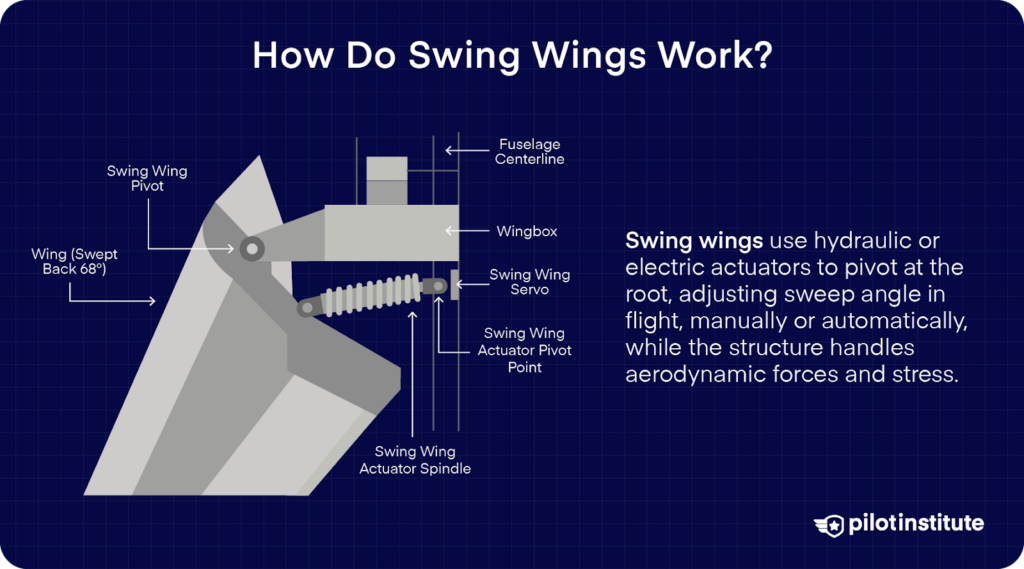

Mechanical Systems

There are complex systems in their mechanism that manage multiple things at once. These systems control the wings, but engineers also take structural integrity and aerodynamic balance into consideration.

Swing wings are mounted on pivot points that let them sweep backward and forward. These movements are controlled by hydraulic or electric actuators, which are managed by onboard computers or you, the pilot.

Different engineers came up with various designs for changing the wing sweep. But to give you a general idea, let’s look at the F-111 aircraft as an example.

The wings swing back and forth using a hydraulic system (powered by fluid pressure). You can adjust the wings using a manual control in the cockpit.

The F-111 has two main hydraulic arms, one for each wing, and they work together to make sure both wings move simultaneously.

The best part about having two hydraulic arms? If one hydraulic system fails, the other one can still move both wings, thanks to a mechanical link between them.

Then, rollers automatically engage if hydraulic pressure is lost, or when a desired sweep angle is set to secure the wings firmly in position. This prevents any unintended movement from the wings.

Adjustment Methods

There are actually two primary methods for adjusting wing sweep: manual and automatic.

Manual Control

The F-111 in our example makes use of manual systems. When your aircraft has this system, you’re in charge of adjusting the wing position based on flight conditions.

You’ll have direct control over the wing configuration. This configuration lets you make adjustments for specific maneuvers or mission requirements.

Automatic Systems

But as aircraft designs have become more advanced with time, modern ones can now also be equipped with automatic systems. As your airspeed changes, the wing sweep angle adjusts accordingly.

Sensors and onboard computers determine the optimal wing position. Adjustments can be made with mechanical precision, plus you’ll have a lighter workload.

Which one is better? It depends on how you fly. Of course, it all comes down to the aircraft’s design and its intended operational use.

Structural Considerations

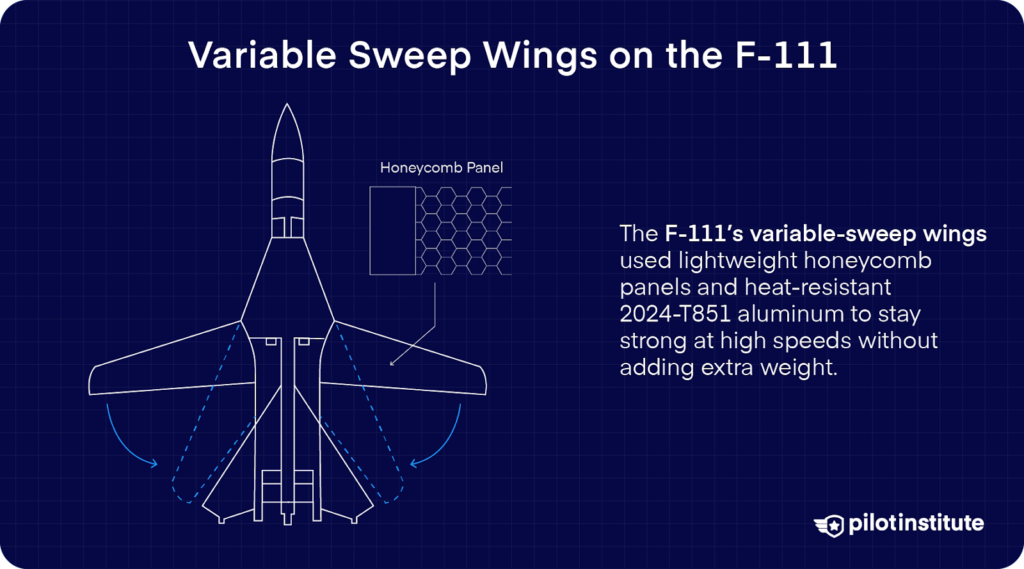

As the sweep angle changes in flight, your aircraft encounters different structural stresses. Not to mention, they also make your aircraft heavier. That’s why you should also consider the composition of your aircraft, especially its wings.

Airframe

More parts mean more weight, so how did designers solve this problem? The outer parts of the F-111’s body were mostly made of honeycomb-sandwich panels. These panels are built like a sandwich.

They have two thin, strong outer layers with a lightweight honeycomb structure in the middle. The honeycomb part is made of aluminum and looks like a beehive with lots of tiny, hollow hexagons.

Two important parts of the wing were the top and bottom surfaces, and they were made from 2024-T851 aluminum. Because the F-111 flies very fast, its wings can get very hot during flight. At those high temperatures, some metals become weaker.

But even though this material isn’t as strong as other aluminum types at normal room temperature, it actually performs better than those other types when things heat up. That’s why it was chosen for the job.

Sweep System

The wing sweep system uses a single pin to let the wing rotate. To make sure the system doesn’t get overloaded, it includes two separate paths to share the stress.

The carry-through box that connects the wings through the aircraft, however, is built as one solid piece.

Why one solid piece? It’s designed so it can be easily removed and reattached to the body of the aircraft, which makes maintenance easier.

This carry-through box also holds fuel as part of the aircraft’s forward fuel tank. To keep everything working smoothly, the moving parts use a dry lubricant, and double seals keep out dirt and other particles.

Advantages of Variable-Sweep Wings

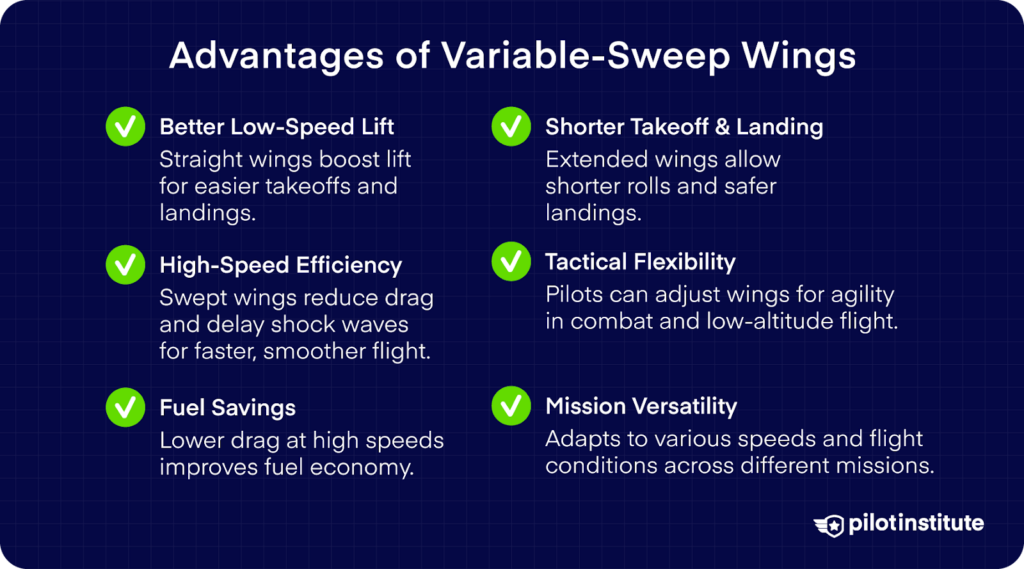

Optimized Performance Across Speeds

One of the primary advantages of swing wings is their versatility across different speeds. At lower speeds, extending the wings straight out increases lift.

But when you’re doing high-speed dashes, sweeping the wings back will reduce drag. You’ll achieve better efficiency and speed during high-speed flights.

Swing wings help your aircraft perform at its best in different mission profiles. Variable-sweep wings maximize aerodynamic efficiency at different flight speeds.

Improved Takeoff and Landing

Swing wings enhance takeoff and landing performance by allowing wings to extend during these critical phases. The lift coefficient increases when you extend the wings.

What else does this mean for your aircraft? Shorter takeoff rolls and lower landing speeds.

For example, the Panavia Tornado‘s design includes features that allow for excellent low-speed handling and landing characteristics. These make the aircraft well-suited for short-field operations.

High-Speed Efficiency

But the advantages don’t just stop there. At high speeds, especially near or above the speed of sound, swept-back wings actually lessen aerodynamic drag by delaying the formation of shock waves.

This reduction in drag leads to better fuel economy and allows for higher maximum speeds without requiring structural modifications. The improved stability at high speeds also contributes to steady flight, and overall better performance.

Enhanced Tactical Flexibility

Variable-swept wings have excellent tactical features that let them quickly adapt to changing scenarios in combat.

They also enable short takeoff and landing distances and good landing performance. It has good gust response characteristics in low-altitude flight.

During dogfights or evasive maneuvers, pilots are able to change wing configurations to manage speed and agility. There’s also a wider operational range of the aircraft since they’re optimized for different phases of your flight.

Disadvantages of Variable-Sweep Wings

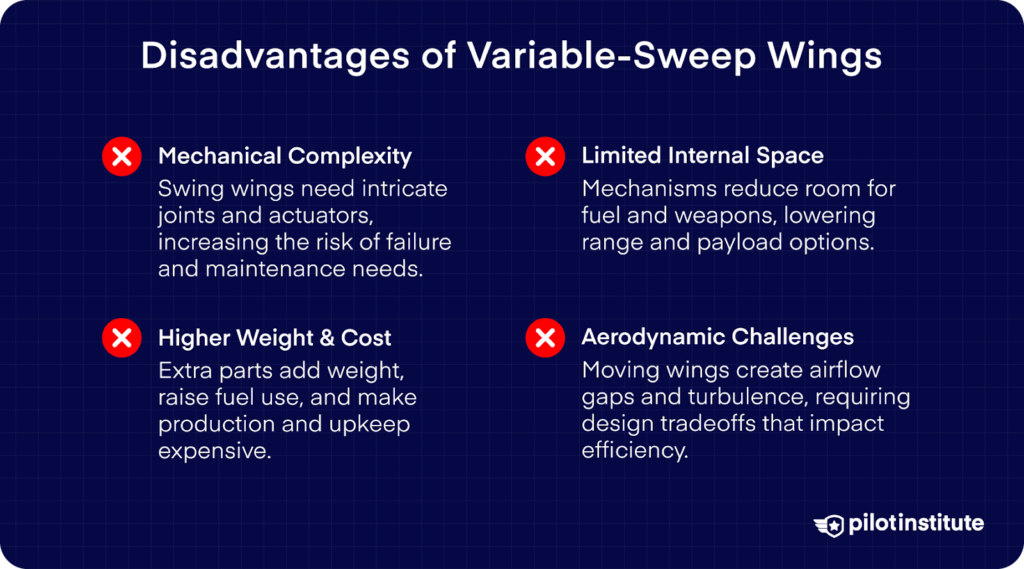

But while the swing-wing sounds like the ideal aircraft, there are reasons why we don’t see them around as much. Variable-sweep wings come with challenges that have proven to be quite tough to overcome.

Mechanical Complexity

As you might expect, the mechanisms in a variable sweep wing are very complex. This design requires intricate pivot joints, actuators, and control systems to function correctly. And while useful, these components also come with additional points where mechanical failures can happen.

The F-111 aircraft experienced issues with its wing attach points. The attach structure needed redesign and testing to make sure it’s reliable.

What else comes along with having complex systems? Complex maintenance. Technicians and maintenance personnel need specialized training to handle these mechanisms. This means higher operational costs and longer downtimes.

Added Weight and Maintenance

All of these systems and moving parts make the airplane’s body heavier and less flexible. For example, the F-14 Tomcat, which was known for being a heavy fighter, incurred high manufacturing and maintenance costs.

The added weight also leads to higher fuel consumption, which adds to your operational costs. So while they were conceptualized to be efficient, the extra weight has held them back.

Reduced Internal Space

The aircraft’s mechanisms occupy a lot of valuable space inside the wings. They take up space that could have been used for fuel, so the range and endurance suffer.

This kind of wing design also makes it harder to attach weapons. Since the wings move, hardpoints have to be specially designed to work with that motion. This can limit where weapons can go and how big or heavy they can be.

Another tradeoff that you need to juggle is payload vs range. For the F-111 and many other similar aircraft, the range decreases as the payload gets heavier.

Aerodynamic Compromises

Variable-sweep wings introduce aerodynamic challenges that must be addressed to maintain flight performance. One such challenge is gap sealing.

The movement of the wings creates gaps that can disturb airflow. On top of that, the hinge points of the swing-wing mechanism can become sources of turbulence and flow separation.

The Bell X-5 is an example of aerodynamic compromise. It used an internal rail system that moves the pivot forward as the wings are swept back.

This was done to partially compensate for the aerodynamic center shift, since its earlier versions had a nose-down problem. But such a system called for a heavier mechanism, which meant a larger fuselage with more parasite drag.

The Decline of Variable-Sweep Wings

Variable-sweep wings were once a hallmark of advanced aircraft design. But as flight control systems evolved with time, there has been less of a need for these swing wings. We’ve only seen a decline in their use in the past decades.

Supercritical Wings

A significant new development is the rise of supercritical wings. These wings are designed to delay the onset of shockwaves and reduce drag at transonic speeds.

According to Robert Gregg, Boeing’s chief aerodynamicist, supercritical airfoils help delay shock waves by managing how pressure waves behave at high speeds.

As an aircraft nears the speed of sound, weak pressure waves can no longer move ahead and instead merge into a shock wave. Supercritical wings reduce this effect, lowering drag, thrust requirements, and takeoff and landing distances.

What does this mean? Lower required thrust, and shorter takeoff and landing rolls.

Blended Wing-Body

Another modern development is the Blended Wing-Body (BWB) design. These are aircraft where the fuselage and wings are merged into a single structure.

Delta Air Lines has also voiced its support for the development of BWB aircraft, and it’s easy to see why. A conventional tubular fuselage carries 12–13% of the total lift compared to 31–43% carried by the centerbody in a BWB. They’re more fuel-efficient and can even cut emissions in half.

Fly-By-Wire

Then there’s Fly-By-Wire (FBW) technology. They replace mechanical flight controls with electronic systems, which means less weight, more payload capacity, and better fuel economy.

On top of that, they also have better responsiveness which allows pilots to fly more smoothly.

High-Lift Devices

High-lift devices have also overtaken the swing-wing, and you’ve probably already used some of them.

Flaps and slats are high-lift devices that enhance lift during takeoff and landing. Now, winglets primarily reduce drag during cruise, improving overall efficiency with a simpler wing design.

Stealth Requirements

Variable-sweep mechanisms have gaps and edges that are hard to shield from radar detection, so their stealth capabilities suffer.

Also, a study on the Radar Cross-Section (RCS) of variable-sweep wing aircraft shows that the sweep angle affects the chance of the aircraft to get detected.

One of the strongest radar reflections happens at the same angle as the wing sweep. What does this mean? When the wing is swept back at—say—30°, then a strong radar return happens at a 30° side angle.

Cost and Maintenance Considerations

Fixed-wing designs are mechanically simpler, which means fewer potential failure points and easier maintenance. This also means that they tend to have longer lifespans than swing wings. And since they’re lighter, operators get to save on fuel costs.

On the other hand, variable-sweep wings can be more expensive to build and maintain. It’s these economic factors that have held back the design for a long time, especially in an era where cost-saving is a huge priority in the military.

Examples of Fixed-Wing Replacements

The introduction of high-performance fighters like the F-15 and F-16 is a clear indicator of the shift towards fixed-wing designs. Add in their advanced avionics and engines, and you get a powerful fixed-wing machine.

The F-16 Fighting Falcon, for instance, is a compact fighter aircraft that is highly maneuverable and has proven itself in air-to-air combat and air-to-surface attack. They provide maximum performance for a comparatively low cost.

The Legacy and Future of Swing Wings

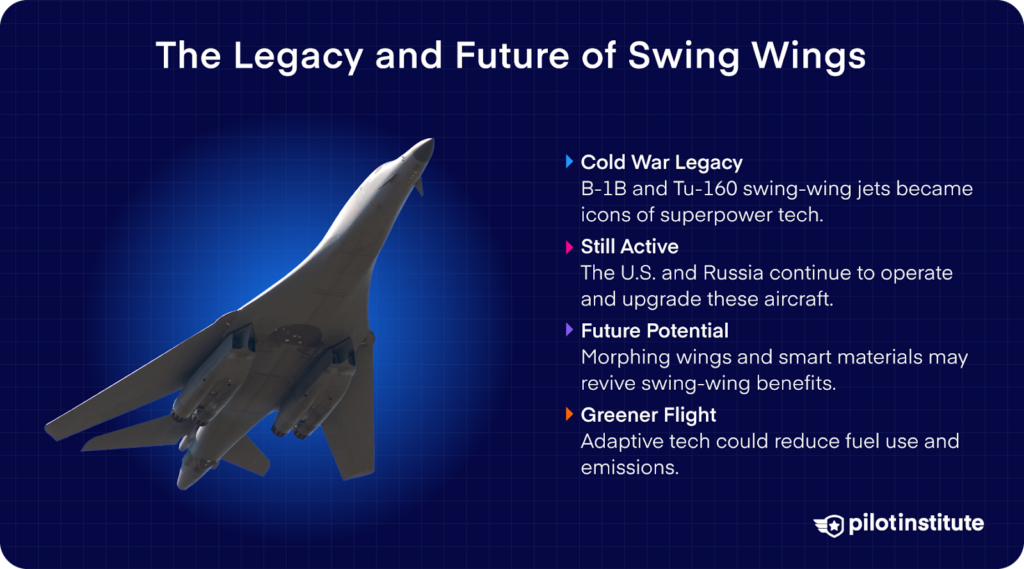

Impact on Aviation History

During the Cold War era, swing-wing aircraft was a symbol of the technological rivalry between superpowers. The United States developed the B-1B Lancer, and the Soviet Union had the Tu-160 Blackjack.

It’s not a stretch to say that these aircraft weren’t just military machines, but also cultural icons. You might see them in old movies and news clips, and they shaped how the public saw the developments in aviation at the time.

Current Use and Potential Future Applications

But despite their decline, some models remain in active service. The U.S. Air Force actually still operates the B-1B Lancer. It is valued for its speed, maneuverability, and its capability to carry the largest conventional payload of both guided and unguided weapons in the Air Force inventory.

Russia is also upgrading its fleet of Tu-160 Blackjack bombers, which was nicknamed the “White Swan.” The Tu-160M modernization program was made to develop its avionics and other systems.

Research into adaptive wings and smart materials shows great promise. Morphing wings take inspiration from how birds fly. They have lightweight actuators made from shape memory alloys, which can deform wings during flight.

These wings can do the same job as older swing wings for a fraction of the weight and size. We could be seeing the start of a swing wing renaissance with less fuel consumption!

Research into Variable Geometry

The idea behind variable geometry is still being developed through new research on adaptive compliant wings. These are special wings that can bend and change shape smoothly, without using the usual moving parts like hinges or flaps.

Because these wings can adjust more naturally during flight, they can reduce drag and even save fuel.

Even AI has seemed to catch up to variable-sweep wings. Future developments could integrate artificial intelligence and advanced sensors for the best aerodynamic performance.

These new wings help aircraft use fuel more efficiently and release fewer emissions. This kind of innovation fits well with sustainability and environmental efforts in aviation.

Conclusion

Variable-sweep wings allowed aircraft to optimize performance across different speeds. They bridged the gap between low-speed handling and high-speed efficiency.

Swing wings marked an adventurous chapter in aviation history, where they serve as a symbol of the relentless pursuit of adaptability and performance in aircraft design.

And while some might call them an obsolete relic of a bygone era, they are something to keep an eye on. After years on the sidelines, variable-sweep wings could soon swing back into the skies.