-

Key Takeaways

-

What Is a Tailless Aircraft?

-

The Role of a Tail in Conventional Aircraft

- Longitudinal Stability

- Directional Stability (Yawing)

-

How Tailless Aircraft Achieve Stability and Control

- Wing Design and Shape

- Airplane News Update

- Use of Reflex Airfoils

-

How to Have Pitch Control Without a Tail

- Elevons and Control Surfaces

- Sweep and Washout

-

Tailless Yaw Control

- Vertical Stabilizers and Rudders

- Alternative Yaw Control Methods

- Proverse Yaw and Wing Design

-

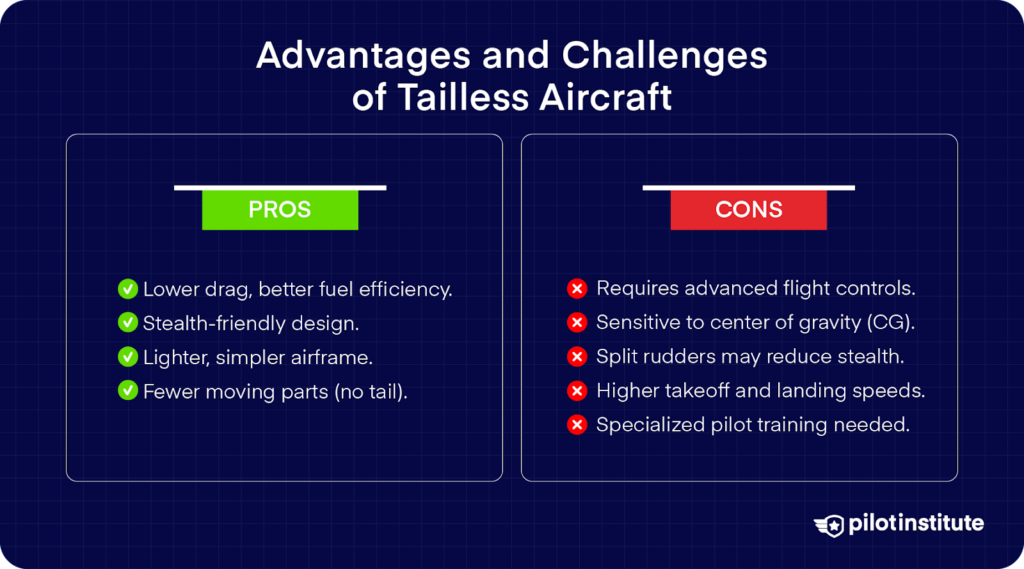

Advantages and Challenges of Tailless Aircraft

- Pros of Tailless Aircraft

- Cons of Tailless Aircraft

-

Historical and Modern Examples of Tailless Aircraft

- Early Pioneers: J.W. Dunne and the Dunne Aircraft

- Horten Brothers and Flying Wings

- Northrop's Contributions

- Tailless Delta-Wing Aircraft

-

The Future of Tailless Aircraft

- Modern Research and Developments

- Potential Applications in UAVs and Drones

- Impact on Future Aircraft Design

-

Conclusion

Have you ever seen an airplane with no tail and no vertical fin, but with just a sleek wing? Ever wondered how it stays balanced? How does it turn or climb without the usual control surfaces?

Tailless aircraft are a reimagination of how an aircraft is supposed to fly. They challenge everything we think we know about flight.

These designs have fascinated engineers for over a century. They prove that with the right aerodynamic tricks, you don’t need a tail to fly.

So, let’s get into the bold innovations that make tailless flight possible, and why it might be the future of aviation.

Key Takeaways

- A tailless aircraft has no other horizontal surface besides its main wing.

- Despite their lack of horizontal control surfaces, tailless aircraft are designed to be stable.

- Tailless aircraft are more efficient and stealthy, but can be more demanding to operate.

- The tailless aircraft has gone through a century of development and may transform future aviation.

What Is a Tailless Aircraft?

A tailless aircraft is a fixed-wing airplane without a horizontal stabilizing surface. This means it lacks features like a tailplane or canard.

With this type of aircraft, the functions of longitudinal stability and control are incorporated into the main wing. A tailless aircraft may still have a fuselage and a vertical tail (fin and rudder).

A tailless airplane is one where everything needed to fly, like lift, control, and stability, is built into the main wing. It’s got no other horizontal aerodynamic surface besides its main wing.

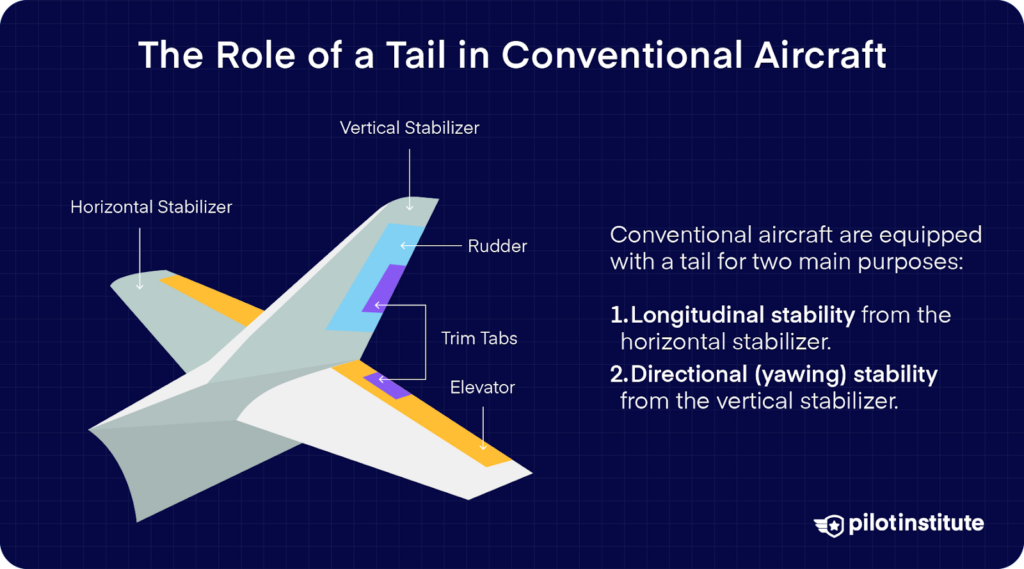

The Role of a Tail in Conventional Aircraft

Conventional aircraft—the ones we typically see—are equipped with a tail for two main purposes:

- Longitudinal stability from the horizontal stabilizer.

- Directional (yawing) stability from the vertical stabilizer.

How does the tail do this? Let’s find out.

Longitudinal Stability

When designing an aircraft, engineers focus a lot on making it stable during flight.

One of the most important types of stability is longitudinal stability. This is all about how steady the aircraft is as it pitches up and down.

Stability in Action

Okay, so how will all of these play out in your flight?

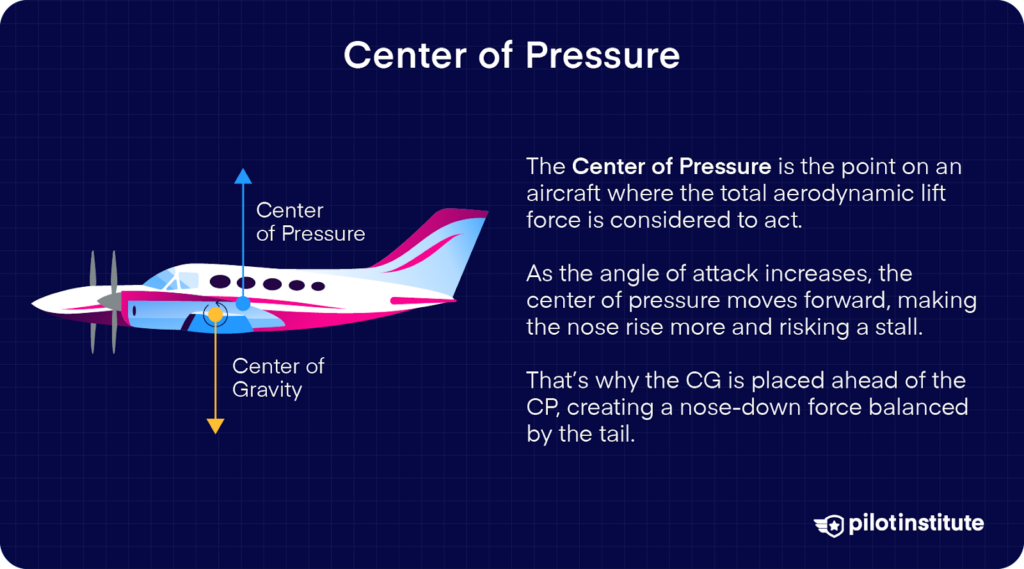

As the Angle Of Attack (AOA) increases, the Center of Pressure (CP) on the wing moves forward. This can make the nose want to rise even more. Worst case, you could end up in a stall.

To prevent this, most aircraft are designed so that the CG is ahead of the CP. This arrangement creates a natural nose-down pitching moment countered by the horizontal tail. The example image shows this as well.

When the aircraft flies faster, the airflow increases, which creates more downward force on the tail. When the aircraft slows down, there’s less airflow, so the tail pushes down less, and the nose starts to dip.

But remember that this will make your aircraft regain speed. Thus, the tail force increases and the nose rises. This up-and-down motion continues, then gradually fades out.

Directional Stability (Yawing)

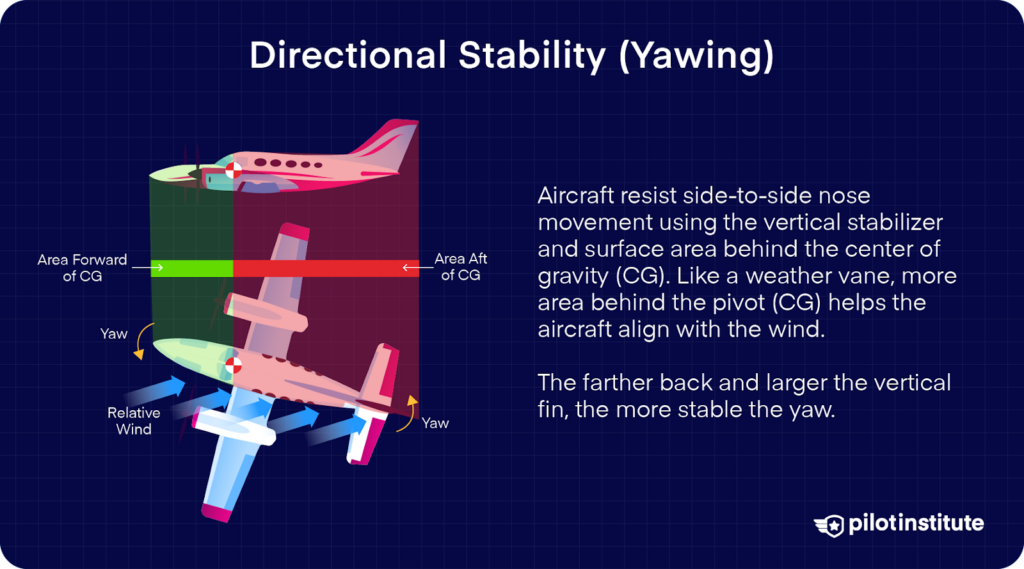

Directional stability, also called yaw stability, is how well an aircraft stays pointed straight as it flies. This also means resisting unwanted side-to-side nose movements.

The Weather Vane

It mostly comes from the vertical stabilizer (fin) and the sides of the fuselage behind the center of gravity.

To help you understand this, imagine a weather vane with the CG as the pivot. If the part in front of the pivot is as big as the part behind it, it won’t turn well in the wind.

To solve this, the back has to be bigger so the wind pushes it around and lines it up. Aircraft work the same way.

In an aircraft, you’ll see more surface area behind the CG than in front. To strengthen this effect, they add a vertical fin at the rear. The bigger and farther back this fin is, the more stable the aircraft is in yaw.

How Tailless Aircraft Achieve Stability and Control

It seems like having a tail is vital for aircraft to achieve stability and control. This now begs the question: How can tailless aircraft achieve them without—well—a tail?

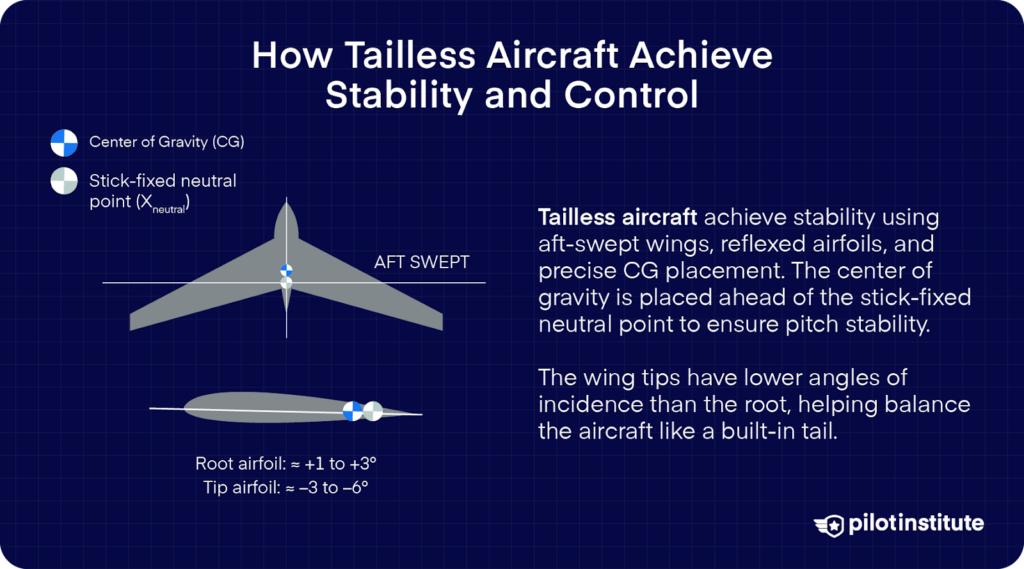

Wing Design and Shape

For tailless aircraft, one of the most important factors for stability is the relationship between the CG and the CP.

Designing for Stability

The CG is typically placed slightly ahead of the CP in tailless designs. This forward placement helps prevent unwanted nose-up pitching. The nose stays level, or drops slightly until it gradually stabilizes.

How are tailless aircraft designed to do this? Mainly two things:

- Sweeping the wing leading edge back, either as a swept wing or delta wing.

- Reducing the angle of incidence of the outer wing section.

These allow the outer wing to act like a conventional tailplane stabiliser.

This design was developed by early aviation pioneer J. W. Dunne. Instead of a tail, the outer parts help balance the aircraft.

In level flight, the aircraft is adjusted so that the wingtips don’t add lift. They might even push down slightly, like a tailplane would. This setup makes the wing less efficient overall, but it can reduce drag, weight, and cost compared to using a separate tail.

Wing Taper and Aspect Ratio

It’s also important to understand wing planform, which is just the shape of the wing when viewed from above. This shape affects how air flows over the wing in three dimensions.

Aspect Ratio

One key feature in planform design is aspect ratio. This is the ratio of the wing span to the wing chord. Long, narrow wings have a high aspect ratio. Short, wide wings have a low aspect ratio.

Why does this matter? High aspect ratio wings reduce drag and improve performance during climb or slow flight. But they also require stronger, heavier structures.

On the flipside, a decrease in aspect ratio will result in higher drag. Designers often need to find a balance between better aerodynamics and added weight.

Taper Ratio

Taper ratio refers to how the wing gets narrower (or thinner) from the base (near the fuselage) to the tip. Tapered wings reduce induced drag and structural weight, especially at high speeds.

They also improve lift distribution and aerodynamic efficiency, and can be designed to achieve a higher maximum lift coefficient before stall, usually when combined with wing twist (washout).

What’s more, they’re lighter and more efficient than rectangular wings.

Use of Reflex Airfoils

Ever notice how many tailless aircraft have wings that curve at the trailing edge? This type of design is a reflex airfoil.

Flying wings don’t have tails or elevators. So instead, their wings are designed with a reflexed trailing edge. They’ve got a slight upward curve at the back of the wing. The reflexed shape of the airfoil usually causes a positive (nose-up) pitching moment coefficient at its aerodynamic center.

This feature lets the aircraft’s center of gravity sit in front of the aerodynamic center. This helps with longitudinal stability and eliminates the need for downforce from a tailplane.

A disturbance can make the nose tilt up or down. This change affects the aerodynamic forces and moments on the reflexed wing. Together with the CG location, these factors help return the aircraft to its trimmed flight attitude.

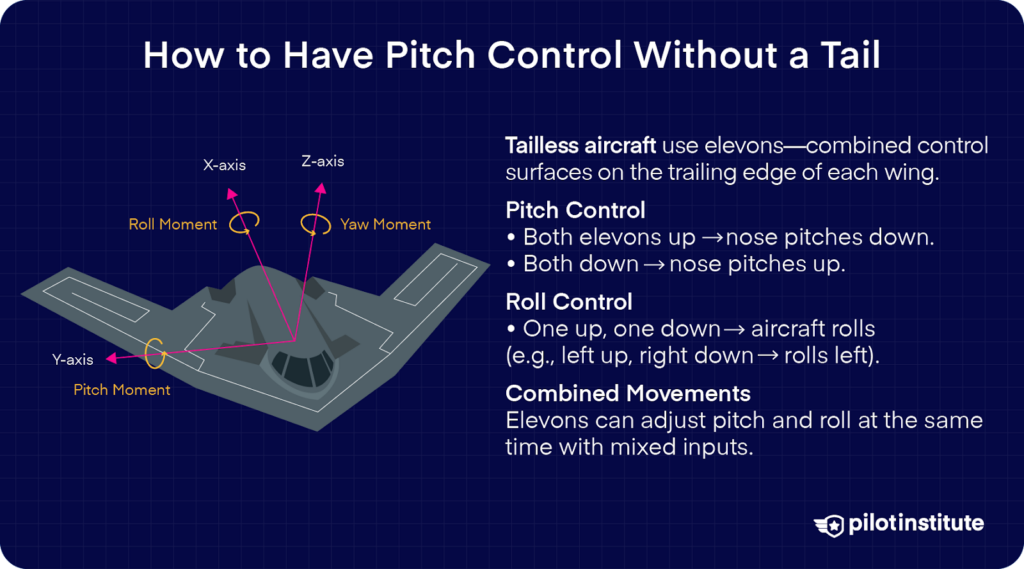

How to Have Pitch Control Without a Tail

Another important part of the tail of conventional aircraft is the elevator. They’re a primary control surface, and you need them to control pitch. So, how can you do the same in a tailless aircraft?

Elevons and Control Surfaces

An ingenious solution is to combine the elevator and aileron, which gives you: the elevon.

In tailless aircraft, elevons serve a dual purpose. They combine the functions of elevators and ailerons. They’re typically installed on each side of the aircraft at the trailing edge of the wing, where the ailerons typically are.

Like in a conventional aircraft, you’ll still have a yoke or stick in the cockpit to control pitch and roll. But how do elevons help you do this?

Pitch Control

When both elevons move symmetrically in the same direction—either up or down—this creates an effect similar to a typical elevator.

- Upward Deflection: Raising both elevons decreases the camber of the wing. Lift is reduced, and the nose pitches downward.

- Downward Deflection: When the elevons are lowered, the camber increases. This creates an increase in lift, and the nose pitches up.

Roll Control

Differential deflection happens when one elevon moves up while the other moves down.

- Left Elevon Up, Right Elevon Down: This configuration decreases lift on the left wing and increases lift on the right wing. As a result, the aircraft rolls to the left.

- Right Elevon Up, Left Elevon Down: Conversely, your aircraft will roll to the right.

Simultaneous Pitch and Roll Control

Elevons can be manipulated to produce both pitch and roll movements simultaneously.

For example, what do you think will happen if the right elevon is deflected fully downward and the left elevon is deflected partially downward?

The aircraft will experience a combined effect: an overall increase in lift, which will pitch the nose up. Then, you’ll have a roll to the left due to the differential lift between the wings.

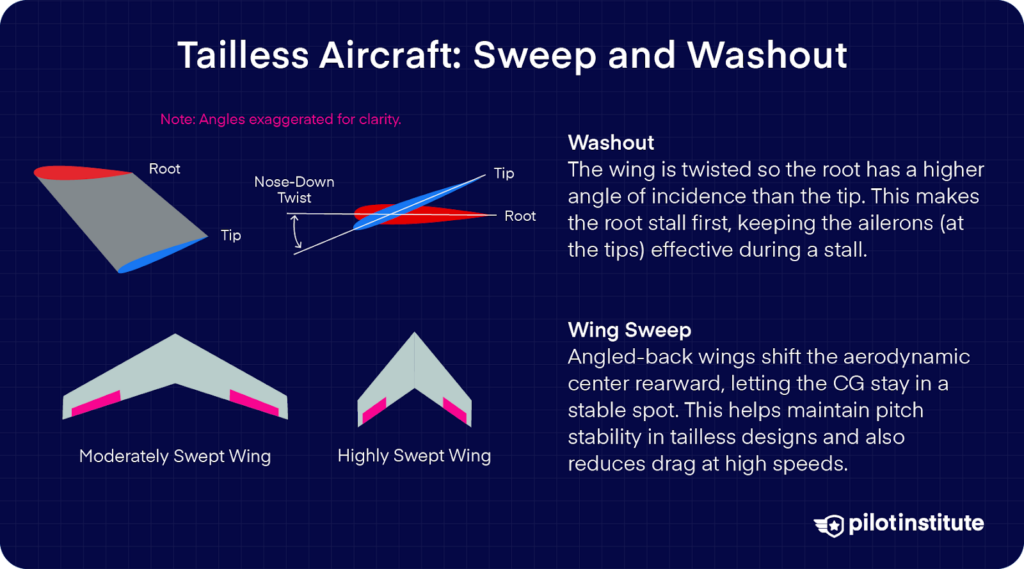

Sweep and Washout

Washout is a design feature where the wing is slightly twisted so that the angle of incidence is higher at the wing root and lower at the tip. This means the wingtip is angled slightly downward compared to the root.

Why design an aircraft this way? With washout, the wing root stalls before the tip. This is important because the ailerons are usually located near the wingtips.

Wing Sweep and Lift Distribution

Ever seen an airplane with the wings angled backward instead of being straight across? This feature is called sweepback, or wing sweep.

In most cases, wings are swept to achieve higher speeds. They also reduce the onset of pressure drag over the leading edge.

But in the case of tailless aircraft, wing sweep is a key design feature for achieving stability. With sweep, the wing’s Aerodynamic Center (AC) is effectively shifted aft.

This rearward shift of the AC allows the CG to be placed in a stable position relative to this new AC. Alternatively, it can increase the moment arm for the outer, stabilizing portions of the wing.

Tailless Yaw Control

Vertical Stabilizers and Rudders

In conventional aircraft, directional stability and controlling yaw is done by the vertical stabilizer. It helps keep the aircraft aligned with the oncoming airflow and counteract adverse yaw. The rudder allows you to make controlled yaw movements.

But while the defining feature of tailless aircraft is the absence of horizontal tail surfaces, some designs—particularly ‘all-wing’ aircraft that also lack conventional vertical fins—achieve directional stability through clever aerodynamic design and specialized control surfaces.

For instance, certain flying wing configurations incorporate blended surfaces to provide necessary directional control.

Take the Northrop B-2 Spirit, for example. How does it manage yaw control? Well, it makes use of sophisticated elevons that can also function as split rudders (or drag rudders).

When the trailing edges of these surfaces split and bend in different ways, they create uneven drag on the wingtips. This creates yawing moments, which help with directional control.

Alternative Yaw Control Methods

Differential Spoilers

Another technique involves the use of differential spoilers. Same as the split rudders, they can be deployed asymmetrically to increase drag on one side. The aircraft then turns to the side with more drag.

This is particularly useful in stealth aircraft. Features like this minimize Radar Cross-Section (RCS), how visible an aircraft is to radar. These control systems also make for a sleeker profile and improved performance.

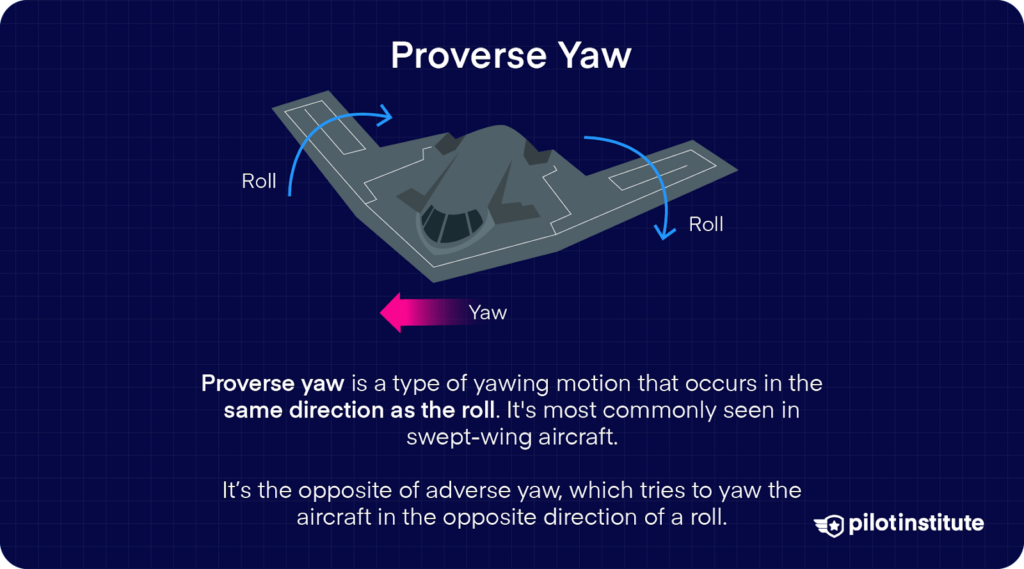

Proverse Yaw and Wing Design

Proverse yaw is a phenomenon where an aircraft yaws in the same direction as it rolls. Proverse yaw enhances maneuverability and stability, particularly in tailless aircraft designs.

How is this achieved? One method is through a bell-shaped lift distribution across the wingspan.

This distribution concentrates lift towards the center of the wing and reduces it towards the tips. As a result, it creates induced thrust at the wingtips rather than induced drag.

Reimar Horten utilized the bell-shaped lift distribution to achieve yaw stability in his aircraft.

His designs, such as the Horten Ho 229, demonstrated that careful wing shaping and lift distribution could eliminate the need for traditional tail surfaces. Drag is reduced, and stealth characteristics are improved.

Advantages and Challenges of Tailless Aircraft

So, is a tailless aircraft the right one for you? Before you decide, it’s important to weigh the pros and cons of flying such a machine. Let’s discuss, and we’ll start with the good parts.

Pros of Tailless Aircraft

Reduced Drag and Increased Efficiency

Since there is no tail assembly, tailless aircraft reduce parasitic drag, which is the resistance caused by non-lifting surfaces. There is also less form drag and interference drag, which improves aerodynamic efficiency.

The reduction in drag allows tailless aircraft to achieve better fuel economy. With less resistance, the aircraft can fly with more range and endurance.

Stealth Characteristics

Tailless designs often feature smooth, continuous surfaces without protruding structures. This design helps in deflecting radar waves away from the source, making it less detectable by radar systems.

That’s why they’re ideal for military missions. Being tailless helps the military avoid enemy detection and enhances the survivability of their pilots.

Structural Simplicity

Eliminating the separate horizontal tail assembly helps make the structure simpler and lighter. In designs that also omit vertical stabilizers, there are fewer large airframe components.

Tailless aircraft have control surfaces like elevons. Elevons work as both elevators and ailerons. They also use special yaw control systems. These features can be complex both aerodynamically and mechanically.

The absence of tail structures also makes for a lighter airframe. Lesser weight only contributes to better performance, like increased payload capacity and improved fuel efficiency.

Cons of Tailless Aircraft

Of course, it’s also important to discuss their downsides.

Swept Wings and Pressure Drag

Tailless designs use swept wings for stability, but this can increase induced drag at low speeds and require higher takeoff and landing speeds. Sweep reduces wave drag at high speeds but can hurt low-speed efficiency.

Limitations of Split Rudders

In the absence of traditional vertical stabilizers, tailless aircraft could use split rudders for yaw control. Split rudders help with yaw control without needing a vertical fin.

However, they can get in the way of your aircraft’s stealth capabilities. When the deflection angle is 45°, the average opposite direction RCS is significantly higher compared to a 0° deflection angle.

What does this mean? The structure of the rudder has a significant impact on the RCS characteristics of the whole aircraft.

Sensitivity to CG Placement

Tailless aircraft are particularly sensitive to CG location. How will this look? Having a forward CG helps with pitch stability but may reduce maneuverability, while an aft CG makes your aircraft more agile but less stable.

Necessity of Advanced Control Systems

Some tailless designs aim for high performance or stealth. They may also have relaxed stability for better maneuvering.

These setups often use advanced control systems, such as fly-by-wire. This helps keep stability and improves handling.

Many tailless aircraft can be made stable. They achieve this through aerodynamic features like wing sweep, washout, and reflexed airfoils.

Increased Demands on Pilot Training

Operating tailless aircraft can be more demanding. You’ll likely need specialized training to handle their unique flight characteristics. You have to be adept at managing the aircraft’s sensitivity to control inputs, and be prepared for unfamiliar responses at different flight phases.

Historical and Modern Examples of Tailless Aircraft

Tailless aircraft have always pushed boundaries. It’s been over a century of experimenting and testing, as pioneers have tried to perfect the flight of tailless aircraft.

Early Pioneers: J.W. Dunne and the Dunne Aircraft

In the early 1900s, British designer J.W. Dunne was among the first to pursue tailless aircraft. The Dunne D.5 and D.8 featured swept wings. A key part of their design for stability was the wing’s conical curve on top. This shape created a washout that increased towards the tips.

His monoplane designs often had downturned wingtips. His biplanes often featured vertical endplates at the wingtips.

These models were ahead of their time, but Dunne’s work proved that controlled flight was possible even without a tail.

Horten Brothers and Flying Wings

Three decades later, in Germany, the Horten brothers developed flying wings like the Horten Ho 229. This is a jet-powered tailless aircraft with low aerodynamic drag.

Their primary goal was aerodynamic efficiency, leading to designs like the Horten Ho 229, a jet-powered tailless aircraft.

The inherent shape of such flying wings also offered low radar observability, a characteristic that later became a significant military advantage, and their work laid groundwork for future stealth aircraft like the B-2.

Northrop’s Contributions

Jack Northrop brought the flying wing concept to the U.S. It all began with prototypes like the N-1M, and progressed to bombers such as the YB-35 and YB-49.

While testing these models was—simply put—disastrous, they demonstrated the potential of tailless designs.

His vision was finally realized in the B-2 Spirit, which succeeded with fly-by-wire technology and structures optimized for stealth.

Tailless Delta-Wing Aircraft

Delta-wing aircraft also fit into tailless design. The Dassault Mirage series proved the concept viable in combat. They’re known for their speed, agility, and simplicity.

The Concorde, though civilian, showcased a delta-wing tailless layout in a supersonic airliner.

The Future of Tailless Aircraft

All thanks to these pioneers, tailless aircraft are more stable than ever. But it’s time to look forward—to the future—where the tailless aircraft seems to be flying a promising path.

Modern Research and Developments

Current research into tailless and Blended Wing Body (BWB) designs is advancing rapidly.

NASA’s X-48 project, in collaboration with Boeing, showed potential of BWB configurations to enhance fuel efficiency and payload volume. These designs integrate the fuselage and wings into a single structure.

Potential Applications in UAVs and Drones

Tailless designs are quite well-suited for Unmanned Aerial Vehicles (UAVs). They are simple, light, and stealthy.

In military contexts, designs like these are used for reconnaissance and combat missions, as shown by aircraft like the Northrop Grumman RQ-180 stealth drone.

In the civilian sector, tailless UAVs are used for surveillance, environmental monitoring, and delivery services.

Impact on Future Aircraft Design

Looking ahead, tailless aircraft designs have the potential to revolutionize commercial aviation.

These designs can even help the environment, thanks to their lower fuel consumption. Progress in materials science and aerodynamic modeling is also supporting their development.

Nonetheless, there are also challenges that need to be addressed, like passenger comfort and adapting to current airport infrastructure.

Conclusion

Tailless aircraft use clever control surfaces to stay stable and maneuverable without a traditional tail. They reduce drag, boost fuel efficiency, and improve stealth, though they also bring challenges like weight sensitivity and the need for advanced flight systems.

We’ve caught a glimpse of early pioneers to today’s stealth drones and flying wings. They’ve shown how innovation drives aviation forward. They continue to inspire engineers looking for better, more efficient ways to fly.

In short, tailless aircraft prove that with clever design, we can overcome big aerodynamic challenges—and shape the future of aviation.