-

Key Takeaways

-

What Is a Four-Stroke Engine?

-

Main Components of a Four-Stroke Engine

- Cylinders

- Pistons

- Crankshaft

- Connecting Rods

- Valves

- Camshaft

- Spark Plugs

- Engine Block

-

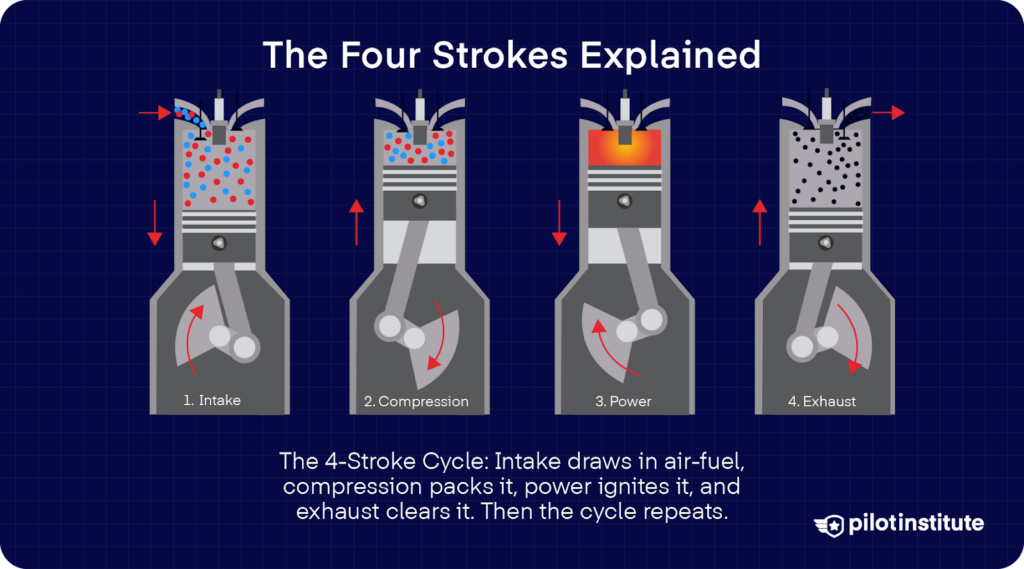

The Four Strokes Explained

- 1. Intake Stroke

- 2. Compression Stroke

- 3. Power Stroke

- 4. Exhaust Stroke

-

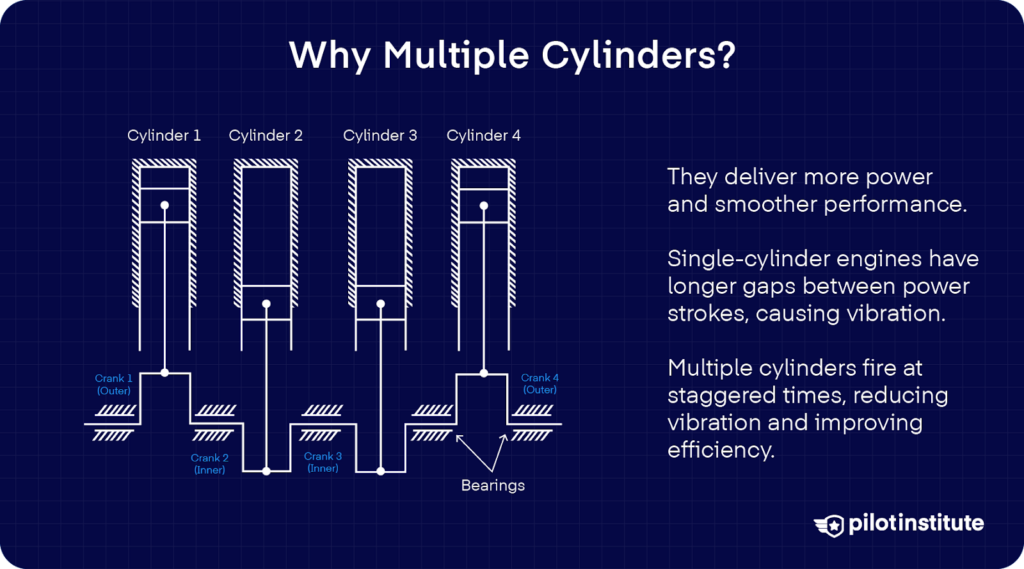

How Four-Stroke Engines Work Together

- Multiple Cylinders

- Firing Order

- Engine Configurations

-

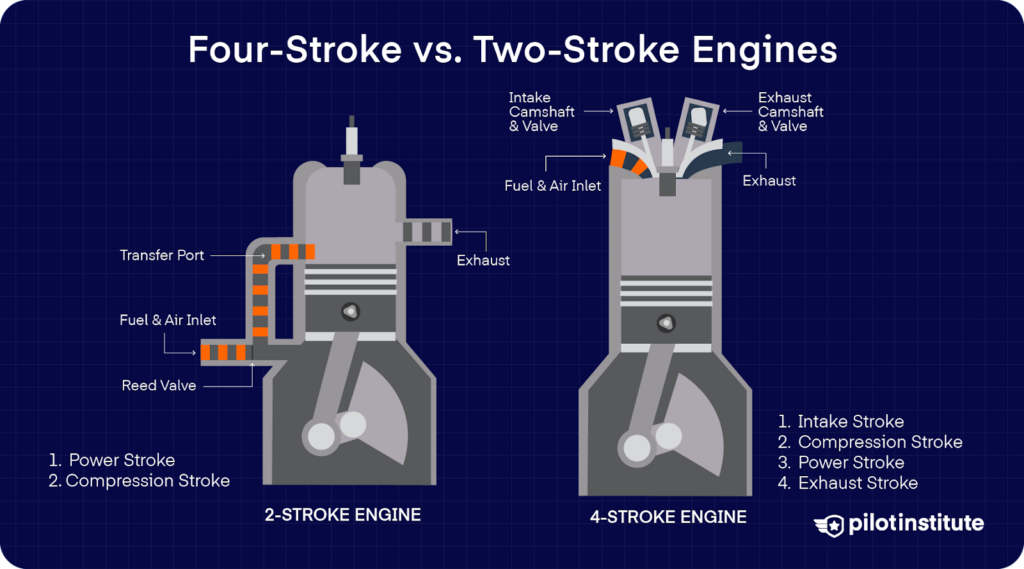

Four-Stroke vs. Two-Stroke Engines

- Operational Differences

- Advantages of Four-Stroke Engines

- Advantages of Two-Stroke Engines

-

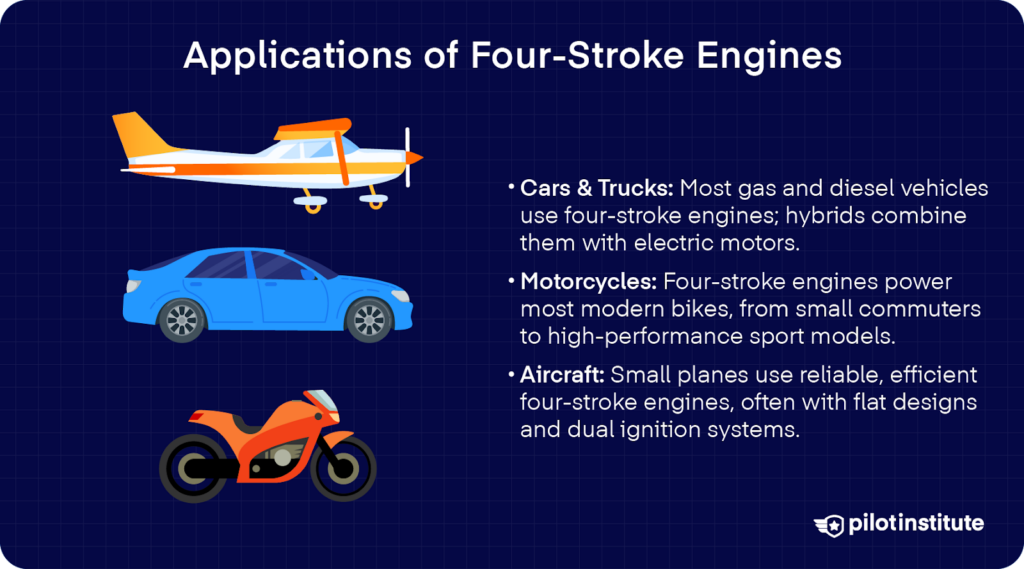

Applications of Four-Stroke Engines

- Automotive Industry

- Motorcycles

- Aviation

-

Maintenance of Four-Stroke Engines

- Regular Maintenance Practices

- Tips for Longevity

-

Future of Four-Stroke Engines

- Technological Advancements

- Environmental Impact

- Emerging Trends

-

Conclusion

Did you know the engine powering your Cessna is very similar to the one in your car?

Yes, one drives a propeller and the other powers wheels. But both vehicles use what’s called the four-stroke combustion engine. Here’s how it works.

Key Takeaways

- A four-stroke engine has four piston movements in one cycle: intake, compression, power, and exhaust.

- Engines have cylinders, pistons, camshafts, valves, spark plugs, and a crankshaft.

- Four-stroke engines are more fuel-efficient, cleaner, and durable than two-stroke engines.

- Modern engines use advanced materials and technology for greater efficiency.

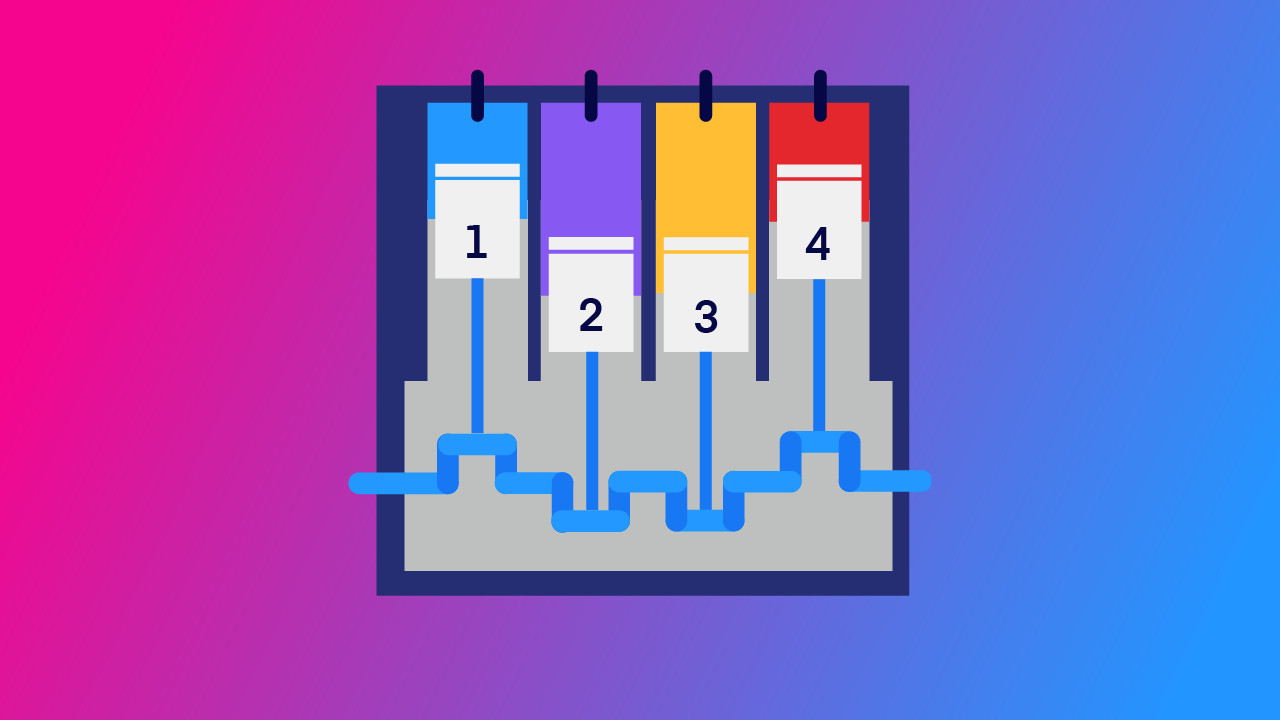

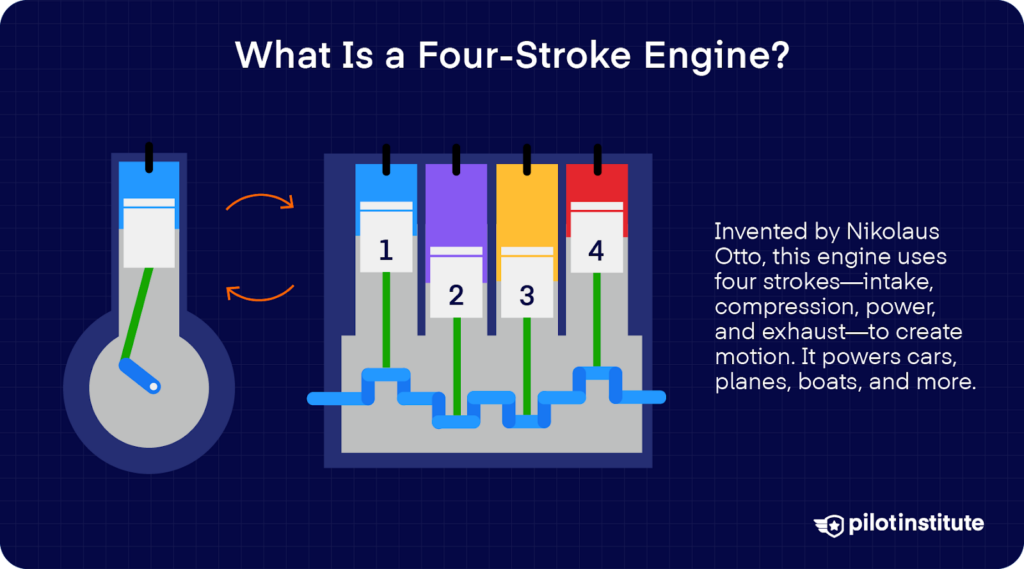

What Is a Four-Stroke Engine?

A four-stroke engine is an internal combustion engine that produces power by completing four piston movements, each called a “stroke.”

The four strokes are:

- Intake

- Compression

- Power

- Exhaust

In a single stroke, the piston travels from the top of the cylinder to the bottom or vice versa.

This design was first developed in the late 1800s by Nikolaus Otto, whose work gave us what we now call the “Otto cycle.”

Almost 150 years later, you’ll find four-stroke engines everywhere. Anything from cars and motorcycles to general aviation aircraft, boats, and heavy equipment uses the four-stroke engine.

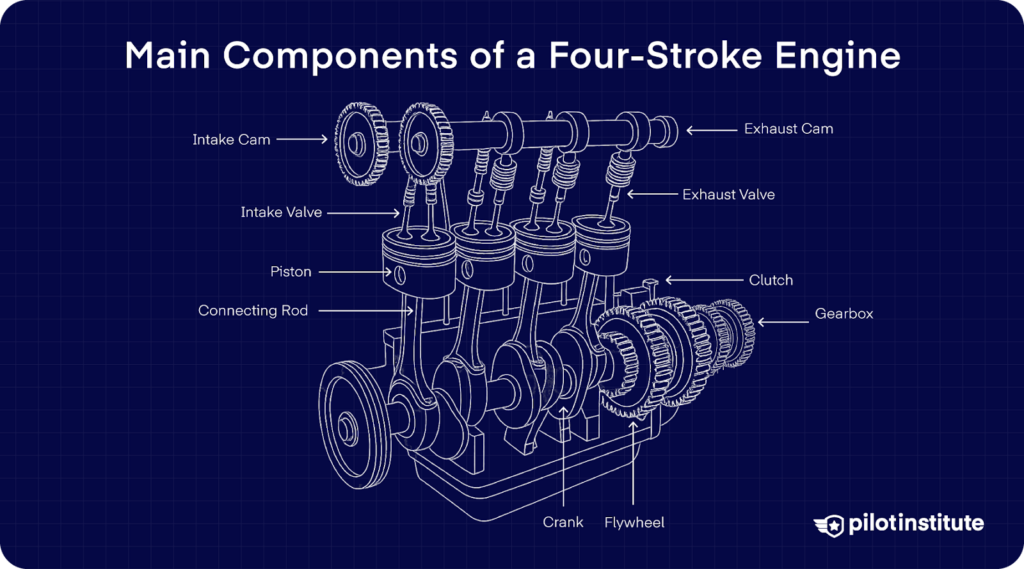

Main Components of a Four-Stroke Engine

Cylinders

The cylinder is a hollow metal tube where all the action happens. It houses the piston, and its top part forms a sealed space for combustion.

Engine cylinders are made from cast iron or aluminum alloy, chosen for their strength and ability to withstand heat.

In many engines, especially air-cooled aircraft engines, the cylinders will have cooling fins outside to help shed heat into the airflow.

In water-cooled engines, the cylinders are surrounded by channels through which coolant flows to carry away heat.

While you can have a fully functioning engine with just a single cylinder, most engines have multiple cylinders arranged in banks. Having multiple cylinders offers smoother power delivery and high performance.

Pistons

The piston is a cylindrical piece of metal that fits snugly inside each cylinder and moves up and down. It’s often made of aluminum alloy for its light weight and good heat conductivity.

The piston’s primary function is to transfer the force of combustion down to the crankshaft.

Piston rings are an important part of the piston. These circular metal rings fit into grooves around the piston’s circumference.

Piston rings serve a few important purposes:

- They seal the combustion chamber and ensure that high-pressure gases from combustion don’t leak past the piston. This sealing is crucial for maintaining compression and power.

- They control the oil quantity in the cylinder. On each stroke, one or more piston rings scrape excess oil off the cylinder walls. This prevents too much oil from entering the combustion chamber, where it would burn and cause smoke.

- They help transfer heat from the piston to the cylinder wall, preventing the piston from overheating.

Piston rings are typically made of hardened steel or cast iron and must maintain a close fit against the cylinder walls.

Crankshaft

The crankshaft’s job is to convert the up-and-down motion of the pistons into rotational motion that can drive a load. Then it can turn a car’s wheels or an aircraft’s propeller.

The crankshaft is usually made of forged or cast steel for strength because it handles a lot of force. It has counterweights to balance the weight of the pistons and rods, which helps reduce vibration.

You typically have a heavy flywheel attached at one end of the crankshaft. The flywheel stores rotational energy and helps smooth the engine’s rotation between power strokes.

On the other end of the crankshaft, you have timing chains and usually a pulley to drive accessories like the alternator or water pump.

Connecting Rods

The connecting rod is the link between the piston and the crankshaft. One end of the rod attaches to the piston via a wrist pin that passes through the piston. The other end attaches to the crankshaft at a crankpin journal.

As the piston moves up and down in the cylinder, it pulls and pushes the connecting rod. This, in turn, pulls and pushes the crankshaft to turn.

Connecting rods have to be strong enough to handle the extreme stresses in tension and compression. That’s why they’re typically made from high-strength steel or aluminum alloys. High-performance rods might be made of titanium to save weight while maintaining strength.

Valves

The valves are like the engine’s mechanical “gates,” opening and closing at just the right times to control the flow of gases into and out of the cylinders.

In a typical four-stroke engine, each cylinder has at least two valves: intake and exhaust valves. These mushroom-shaped valves seal against round openings in the cylinder head called valve seats.

These are the two types of valves:

- Intake valves: These valves let fresh air-fuel mixture into the cylinder. They’re designed to flow as much mixture as possible, so they are often slightly larger in diameter than exhaust valves.

- Exhaust valves: These allow the burnt gases to escape out of the cylinder into the exhaust manifold. Because they deal with very high-temperature gases, exhaust valves are often made of special heat-resistant alloys.

Camshaft

The camshaft is responsible for controlling the motion of the valves. It’s just a rod or shaft that runs along the engine, but it has precisely shaped lobes called cams on it.

As the camshaft rotates, these lobes push against valves to open them up at the right time.

Since the valves are spring-loaded, they snap shut as soon as the lobe stops pushing. The shape of the cam lobe determines how far the valve opens and how long it stays open.

How does the camshaft know when to open the valves?

The camshaft syncs with the crankshaft via a timing belt, chain, or gears.

In a four-stroke engine, the camshaft rotates at half the speed of the crankshaft. This makes sense because the valves must open once every two revolutions of the crank.

The timing belt or chain ensures that the camshaft’s position is synced to the crankshaft’s position. If that timing is lost, the valves would open at the wrong times relative to piston movement. That means the pistons would strike open valves, leading to a catastrophic failure.

That’s why maintaining the timing belt/chain is critical in engine maintenance.

Spark Plugs

Simply compressing the air-fuel mixture won’t create combustion in a gasoline engine. You need something to ignite it.

Spark plugs provide a high-voltage arc of electricity that ignites the fuel at just the right moment. If the spark is too early or too late, the engine can run poorly, knock, or lose power.

Over time, the tips of the plug can become fouled by carbon deposits or oil or just wear out. A fouled or worn spark plug might deliver a weak or no spark at all, causing misfires and reduced fuel efficiency.

Pilots often inspect spark plugs regularly, cleaning or replacing as necessary. Car drivers typically replace spark plugs every few years or tens of thousands of miles.

High-quality spark plugs are made of durable materials like platinum or iridium that last a long time.

Aircraft mostly use two spark plugs per cylinder. The reason is redundancy. If one plug or ignition system fails, the other keeps the engine running.

Engine Block

The engine block forms the bulk of the engine’s structure. It houses the cylinders and is bolted below to the crankcase containing the crankshaft. It must be strong enough to withstand the forces and heat from combustion.

Cast iron blocks are very durable and have good wear characteristics for cylinder walls but are heavy.

Aluminum blocks are much lighter and dissipate heat well, but usually use iron sleeves or special coatings for the cylinder bores since aluminum alone would wear too quickly against piston rings.

In water-cooled engines, the block has passages for coolant that circulate around the cylinders, picking up heat and carrying it to the radiator.

In air-cooled engines, such as those in many small aircraft, the engine block has fins outside to allow airflow to pass by and keep the heat in check.

The Four Strokes Explained

1. Intake Stroke

The cycle begins with the piston moving downward from the top of the cylinder.

As it descends, the intake valve opens. A fresh air-fuel mixture flows into the cylinder, pulled in by the low pressure created as the piston retreats. The engine will later compress and ignite this incoming charge to produce power.

The exhaust valve is closed during this stroke.

2. Compression Stroke

Next, the piston moves back up while the intake and exhaust valves remain closed.

This compresses the air-fuel mixture into a much smaller space, increasing its pressure and temperature. The tighter the mixture is packed, the more energy it can release.

3. Power Stroke

Just before the piston reaches the top again, the spark plug fires. The resulting combustion of the air-fuel mixture creates a high-pressure wave of expanding gases, pushing the piston downward with significant force.

This is the only stroke in the cycle that actually produces power. That’s why it’s called the power stroke.

The piston pushes the connecting rod, turning the crankshaft and driving the engine.

4. Exhaust Stroke

Finally, the piston rises once more, but this time the exhaust valve opens.

The burned gases are pushed out of the cylinder and expelled through the exhaust system. With the chamber cleared, the engine is ready for the next intake stroke to begin the cycle all over again.

How Four-Stroke Engines Work Together

Multiple Cylinders

Why have multiple cylinders at all? The simple answer is: to get more power and smoother operation.

A single-cylinder four-stroke engine can only produce one power stroke every two crankshaft revolutions. That means there’s a big interval between power strokes. You can feel the ensuing vibrations in chainsaws or small motorcycle engines.

If you use multiple cylinders, you can time their pistons so that they run at an offset to each other. This leads to far smoother power delivery than a single-cylinder engine.

Firing Order

The firing order is the sequence in which each cylinder goes through its power stroke.

Engineers carefully choose the firing order to ensure the engine runs as balanced as possible. If the cylinders fire in an awkward sequence, the engine could run very roughly, vibrate excessively, or even damage itself.

For example, a common firing order for inline-four engines is 1-3-4-2.

This sequence is arranged so that the power strokes are spaced evenly and opposing movements somewhat cancel each other.

If one were to fire 1-2-3-4 in order, the engine would have a much lumpier operation because the two cylinders next to each other would fire sequentially, and then you’d have a long gap.

Engine Configurations

When multiple cylinders are involved, the arrangement of the engine block needs to be carefully considered. The layout affects not only the operating smoothness but also the engine’s size and fit into a vehicle or aircraft.

- Inline engines have all the cylinders arranged in a single row, one after the other. An inline-4 is very common in cars for its compactness and simplicity. However, if you keep adding cylinders in a single line, the engine can become too long to fit in an engine bay.

- V engines have two banks of cylinders arranged in a V shape. Each bank has half the engine’s cylinders. For example, a V6 has two banks of three cylinders, a V8 has two banks of four, and so on.

The angle between banks affects the engine’s balance. A 90° V8 can be very smooth but takes up more space. - A flat engine, also known as a horizontally opposed or “boxer” engine, has two banks of cylinders directly opposite each other on either side of a single crankshaft, lying flat. Think of a V-engine where the “V” is 180° open.

- In a boxer engine, each pair of opposite pistons moves in and out like boxing gloves punching towards each other, hence the nickname. Boxer engines are extremely smooth since their opposing forces cancel each other out fairly well. Aircraft like the Cessna C172 use a flat-four engine for its smooth operation and compact size.

- Radial four-stroke engines were common in old propeller aircraft for their excellent power-to-weight ratio. Their specialty, however, was their cooling power. Each cylinder is exposed to airflow in a radial arrangement. Unfortunately, this configuration is very bulky, so you won’t find radial engines in most aircraft today.

Four-Stroke vs. Two-Stroke Engines

Operational Differences

In a two-stroke engine, the entire cycle is completed in just two piston strokes. This means that every time the piston goes down, it produces a power stroke.

To achieve this, two-stroke engines combine some of the stages.

As the piston moves down during the power stroke, it also exposes an exhaust port and an intake port in the cylinder wall, allowing exhaust gases to flow out and fresh mixture to be drawn or forced in simultaneously.

As the piston rises, it compresses the new charge and also helps draw fresh mixture into the crankcase or intake area for the next cycle.

Advantages of Four-Stroke Engines

If two-stroke engines get the job done in half the revolutions of a four-stroke engine, why aren’t they more popular?

- Four-stroke engines generally achieve better fuel economy than comparable two-stroke engines. Since intake and exhaust stages are separate and carefully timed, a four-stroke engine tends to burn its fuel more completely and wastes less of it out the exhaust.

- In many two-stroke designs, some of the fresh fuel mixture can slip out of the exhaust port before it gets burned.

- Two-stroke engines often require oil to be mixed with the fuel since they may not have a distinct lubrication system. As a result, two-stroke engines inherently burn some oil as part of regular operation, leading to bluish smoke in the exhaust.

- Two-stroke engines often have a loud, high-pitched, buzzing exhaust note. This comes from the rapid firing and the resonance of the expansion chamber exhausts they often use. Four-stroke engines produce a lower and less unpleasant sound.

Advantages of Two-Stroke Engines

Despite their challenges, two-stroke engines do have strengths.

They have a very high power-to-weight ratio since they produce power at every revolution. They’re very compact and have few moving parts. This simplicity can make them cheaper to manufacture and sometimes easier to repair.

Two-stroke engines were popular in small outboard motors in boats, lawnmowers, and motorcycles. In aviation, ultralights and drones sometimes use these engines due to their compactness and high power-to-weight.

Applications of Four-Stroke Engines

Automotive Industry

Nearly every non-electric passenger car, SUV, and truck on the road today uses a four-stroke internal combustion engine.

Most cars and light vehicles use gasoline (petrol) engines. Many heavy-duty trucks, buses, and other work vehicles use four-stroke diesel engines, which offer high torque and efficiency.

In recent years, hybrid engines have soared in popularity. These still typically have a four-stroke internal combustion engine on board, working in tandem with an electric motor and battery.

Motorcycles

Two-stroke motorcycle engines used to be common, but today four-stroke engines dominate the market.

Smaller bikes like 125cc or 250cc beginner bikes and commuter models use single-cylinder engines.

More powerful bikes have multiple cylinders. Many cruisers have parallel twins and V-twins, and sport bikes may have inline-four cylinders.

Aviation

Most small general aviation aircraft use four-stroke engines to power their propellers. These engines are chosen for reliability above all. They’re designed to be robust, with redundancies like dual spark plugs and magnetos to reduce the chances of engine failure.

Horizontally opposed (flat) engines are popular here for their smoothness and small frontal area.

Four-stroke engines generally provide the efficiency aircraft need and can be leaned out at cruise to burn less fuel.

Maintenance of Four-Stroke Engines

Regular Maintenance Practices

- Regularly replace the engine oil at the intervals recommended by the manufacturer.

- Change the filters. A clean air filter ensures the engine is breathing dust-free air. Changing the oil filter when replacing oil avoids circulating contaminants through the engine.

- Periodically inspect spark plugs and replace them if they look worn out.

- Check your fluids often. This includes the engine oil level and the coolant level for water-cooled engines.

- Inspect belts and hoses and make sure they’re not broken, cracked, or frayed.

Tips for Longevity

- Operate the engine within its intended limits. Avoid overloading or lugging the engine. In a car, that means downshift instead of flooring it in a high gear at low speed. In an aircraft, it means don’t exceed the recommended cruise power settings or climb too steeply without enough air cooling.

- Always use the manufacturer-recommended fuel grade. Bad-quality fuel risks knocking, which can destroy an engine over time. Similarly, use oil of the right type and viscosity.

- Don’t ignore small issues. Minor leaks or odd noises can indicate trouble brewing.

- Follow the maintenance schedule provided in the owner’s manual or POH (Pilot’s Operating Handbook) for your engine.

Future of Four-Stroke Engines

Technological Advancements

Modern engines are becoming smarter.

Computer-controlled systems now adjust timing, fuel delivery, and even valve lift to maximize every drop of fuel while keeping emissions low.

Aircraft engines are moving from carburetors to fuel injection and FADEC systems.

Environmental Impact

As emissions standards tighten, engine makers find ways to run cleaner without sacrificing performance.

Research into alternative fuels like biofuels and synthetic gasoline is ongoing.

Mazda’s new SkyActiv-X engines try to combine the benefits of gasoline and diesel engines by offering Spark-Controlled Compression Ignition.

Emerging Trends

Increased use of materials like magnesium and carbon fiber makes engines lighter and more efficient.

Hybrid systems and start-stop technology are now widespread, especially in cars. This helps reduce fuel use and idle-time emissions.

Conclusion

You depend on your engine to power your journey if you’re flying or driving. Continuing to learn about engines helps you operate and maintain your engine correctly.