-

Key Takeaways

-

What Is Thrust Reversal?

- Definition of Thrust Reversal

- Purpose of Thrust Reversal

-

How Thrust Reversers Work

- Basic Principles

- Components Involved

-

Types of Thrust Reversers

- Target (Bucket) Thrust Reversers

- Clamshell Reversers

- Cascade and Pivot Thrust Reversers

-

Thrust Reversal in Propeller-Driven Aircraft

- Benefits and Use Cases

-

Operational Use of Thrust Reversers

- Effectiveness at Different Speeds

- Limitations and Considerations

-

Safety and Performance Benefits

- Reduced Brake Wear

- Reduced Landing Distances and Enhanced Safety Margins

-

Case Studies and Examples

-

Advances in Thrust Reversal Technology

- Future Developments

-

Conclusion

How do 400 tons of aircraft landing at above 150 miles an hour manage to come to a stop? It’s not just wheel brakes slowing the aircraft on its landing roll. The engines also play a part.

Almost all large aircraft can use reverse thrust to slow the aircraft post-touchdown. We’ll show you how aircraft engines manage to work in reverse and how you can spot them doing their job.

Key Takeaways

- Thrust reversers redirect engine thrust forward to help slow aircraft after landing.

- They reduce brake wear and shorten landing distances, improving safety in tough conditions.

- Types include target (bucket), clamshell, and cascade systems.

- Proper use is essential for safe landings and rejected takeoffs.

What Is Thrust Reversal?

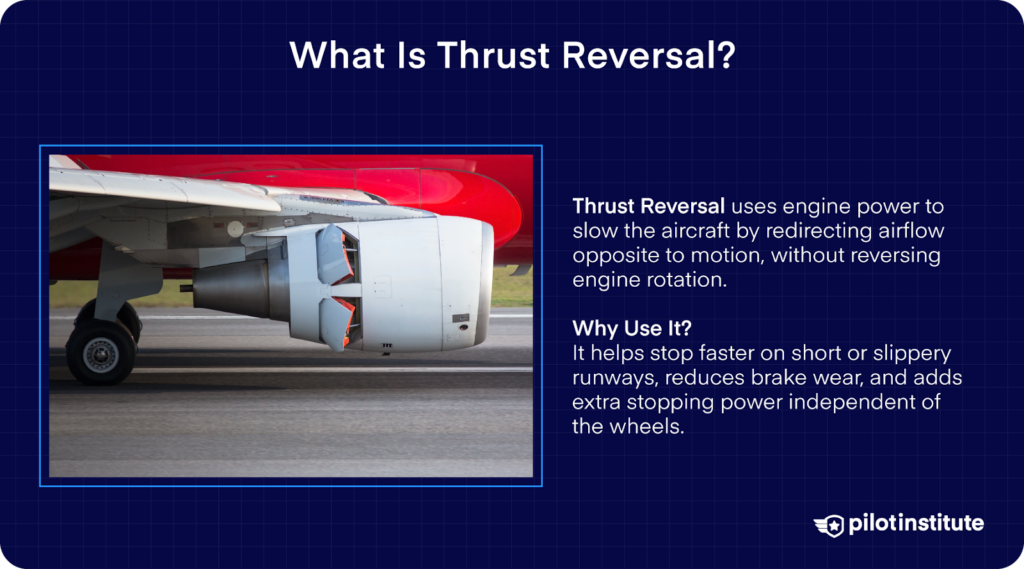

Definition of Thrust Reversal

In aircraft, reverse thrust uses the engines to slow the aircraft down by redirecting their thrust against its motion.

When pilots talk about engaging reverse thrust, they don’t mean spinning the engines or propellers the opposite way. Reverse thrust in aircraft keeps the engines rotating in their normal direction but redirects where the airflow goes as it leaves the engines.

Some aircraft move a special panel behind the engine to reroute the exhaust airflow. Aircraft equipped with propellers change the blade pitch to make it bite the air in the opposite direction.

Purpose of Thrust Reversal

Why bother with reverse thrust when all aircraft already have brakes fitted to their wheels?

Wheel brakes are only as effective as the wheel’s grip on the surface. If the runway is contaminated with water, ice, or oil, the wheel may simply skid over the surface instead of gripping it. Brakes can’t help much in this situation.

Engines are entirely independent of the wheels. As soon as the aircraft touches down, pilots can engage reverse thrust to divide the task of slowing the aircraft down. The extra stopping power is useful for landing on short runways and in adverse conditions.

Even if you feel you have all the runway you need, using reverse thrust lets you reduce using the brakes, which means they don’t wear out quickly, and you don’t have to replace them as often.

How Thrust Reversers Work

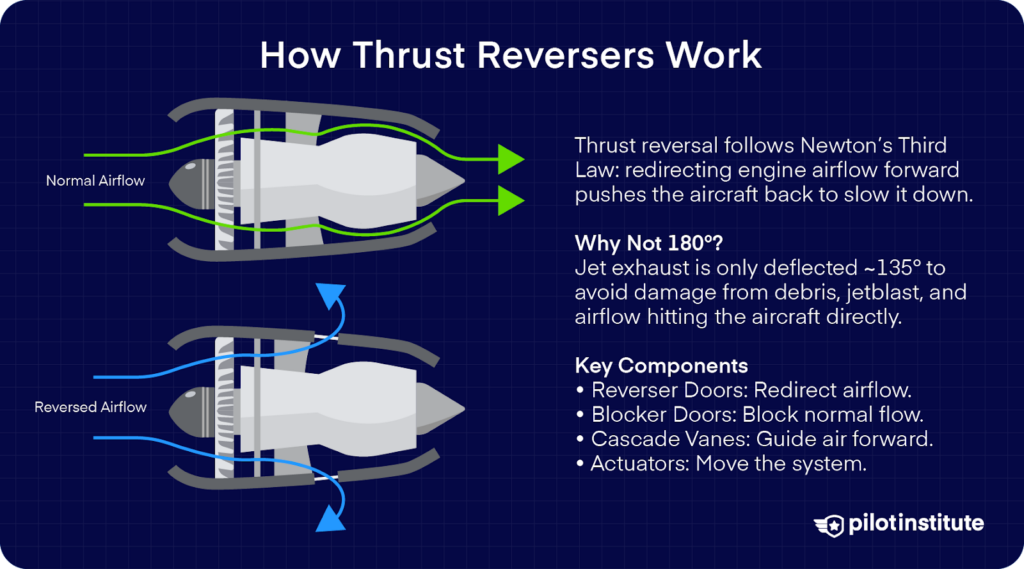

Basic Principles

The basic principle behind thrust reversers is one of the simplest laws of physics: Newton’s Third Law of Motion. This law states, “Every action has an equal and opposite reaction.”

Normally, engines throw exhaust gases or fan airflow backward. The reaction force pushes the aircraft forward. If you were to redirect the mass of air forward, the reaction would push backward against the aircraft, slowing it down.

In reality, jet engine thrust reversers only redirect their exhaust by about 135 degrees, not 180 degrees, which is exactly opposite the normal direction.

Why don’t we turn the airflow around completely?

That’s mostly due to practical reasons. The ducting and piping needed to bend the exhaust 180 degrees would not be easy to fit in an engine nacelle.

Even if you could package it, the jetblast would hit the wings, flaps, and runway straight on. This would kick debris and water into the intakes, risking damage or stalls.

A roughly 135-degree deflection provides enough braking power with minimal components needed.

Components Involved

Since you already have an engine capable of generating more than enough thrust, you only need a way to redirect the exhaust forward.

- Most aircraft use movable reverser doors, panels that deflect the exhaust gases forward. When not in use, they stow neatly so they don’t disrupt normal airflow.

Some aircraft also use additional blocker doors that block the normal (backward) exhaust flow.

Newer aircraft with large (high-bypass) engines use cascade vanes, like louvers, guiding the airflow forward. - Actuators are the mechanisms that physically move all these panels. They may be hydraulic, pneumatic, or electric.

Propeller-driven aircraft perform thrust reversal a bit differently. They don’t need to use any extra components to do the job. We’ll talk more about them later on.

Types of Thrust Reversers

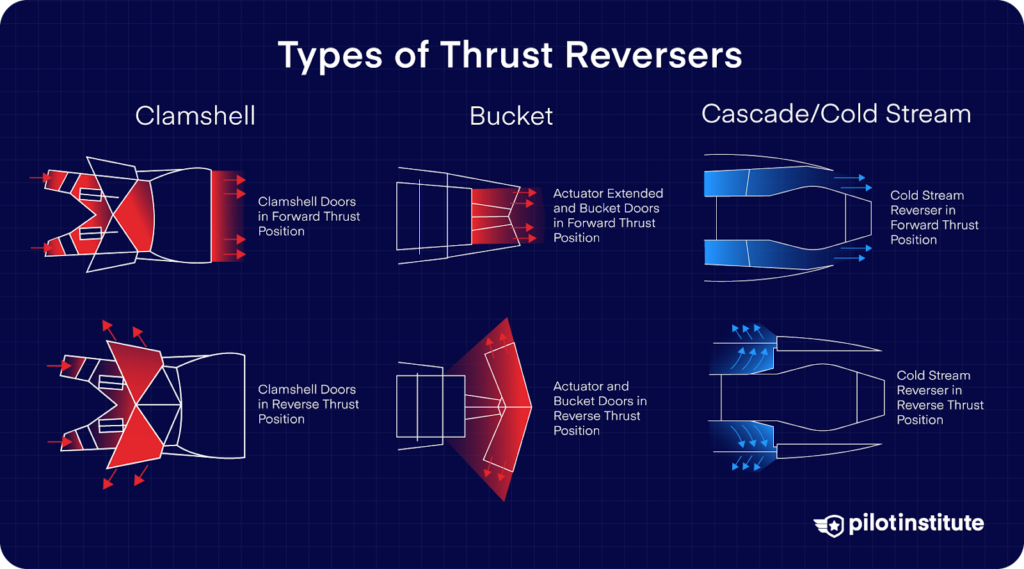

Target (Bucket) Thrust Reversers

This type of thrust reverser is perhaps the easiest to spot when deployed. It has two large bucket-like doors that form the smooth cone shape of the engine’s exhaust nozzle.

When the pilot selects reverse, the buckets swing out and back.

Target or bucket reversers were commonly used on many first-generation turbofan airliners and some military jets.

For instance, early 737 models (737-100/200 with JT8D engines) had bucket reversers. You could see them snapping open on each engine during landing rollout. The Douglas DC-9 is another jet with the same kind of reversers.

These systems are typically hydraulically operated to ensure they can move those big doors quickly and lock them in position against the force of the exhaust.

When deployed, bucket reversers are quite effective at deflecting exhaust gases forward, and dust, water, or smoke often blow toward the front of the engine as they work.

Clamshell Reversers

A clamshell system hides its doors inside the tailpipe. When the pilot selects reverse, those curved doors swing inward like halves of a seashell.

This seals the nozzle throat and forces the exhaust to escape through slots or louvers just ahead of the doors. Because everything happens inside the nozzle, this type of reverser is difficult to spot from the outside.

Clamshell designs were common on earlier turbojet and low-bypass turbofan engines. They are usually pneumatically or hydraulically actuated. They must be built to withstand high temperatures because they handle the hot exhaust gases directly.

One classic example of clamshell reversers could be found on the BAC One-Eleven and some older business jets.

Clamshell reversers are relatively simple and effective but can be noisy and add weight.

Cascade and Pivot Thrust Reversers

The cascade and pivot type thrust reversers are the most common types nowadays. They are specially designed for modern high-bypass engines.

Why did high-bypass engines need a different type of thrust reverser?

High-bypass turbofan engines have a large fan at the front. This fan produces most of the thrust this type of engine generates.

Modern reversers take advantage of this by redirecting the fan’s thrust rather than messing directly with the hot core exhaust, so they are sometimes called “cold-stream” reversers.

How do Modern Thrust Reversers Work?

A cascade reverser system typically consists of a set of cascade vanes (think of them as louvered grills) hidden around the circumference of the engine nacelle, covered by a movable cowling.

In normal flight, the cascade vanes are covered by the nacelle’s outer sleeve, maintaining the engine’s smooth shape.

When reverse is needed, the sleeve slides aft (backward), uncovering the cascade vanes. Simultaneously, blocker doors inside the bypass duct deploy to block the fan air’s rearward flow.

That blocked air is then forced out through the cascade vanes, which are angled to direct the airflow forward.

The result is that the engine’s fan thrust is now spilling out of the sides of the engine nacelle, directed forward/upward, creating reverse thrust.

Because cascade reversers act on the large volume of cooler bypass air, they can produce substantial reverse thrust while avoiding sending the hot core exhaust forward.

The hot exhaust usually continues out the center, still providing a bit of forward thrust, but the net effect with the fan reversed is overall braking force.

Cascade systems are almost invisible when stowed. They also tend to be more aerodynamically efficient when not in use.

You’ll find cascade thrust reversers on almost every modern airliner engine. Some variants use pivoting doors similar to small clamshells to redirect the exhaust.

Thrust Reversal in Propeller-Driven Aircraft

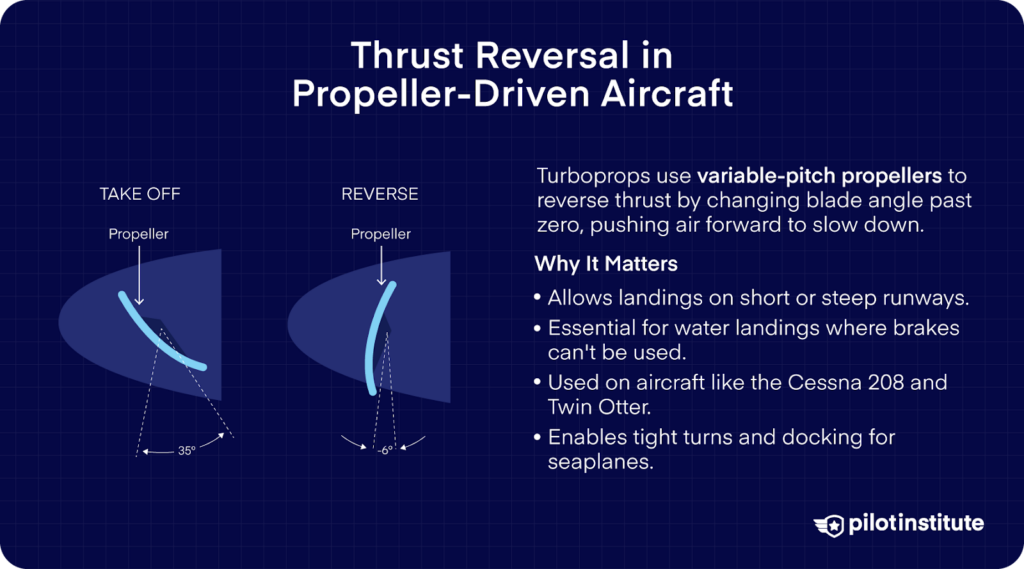

Most people don’t think about propeller aircraft when thinking of reverse thrust.

It’s true that propeller aircraft don’t have extra components making up a thrust reverse system. But they can take advantage of a feature their propeller may already have to produce reverse thrust.

Many turboprops and even some piston engine aircraft have a variable pitch propeller. What does this mean?

With a variable-pitch propeller, the pilot can adjust the propeller’s pitch using a control in the cockpit. Pitch affects how much the propeller blade bites into the air to force it backward. Many variable pitch propellers can have their blade angle decreased past zero to a negative angle.

With this setting, the propeller bites the air in the opposite direction. It pulls air forward and pushes the aircraft backward. That’s how propeller engines produce reverse thrust.

You’ll often hear the propeller change sound when this happens. Unlike jets, where the engine instruments show an increase in power for reverse, reverse is more about blade angle than raw power for turboprops.

Benefits and Use Cases

Propeller aircraft often land at airports with short runways. The ability to instantly reverse prop thrust lets them land in places where jets simply can’t go.

Aircraft like the Cessna 208 Caravan and the De Havilland Twin Otter are often seen at airports with famously short runways or steep approaches, such as St. Barts Island.

Another advantage is for aircraft that land on water, such as floatplanes or flying boats.

Of course, those aircraft can’t use wheel brakes. Reverse-pitch propellers prove very handy in maneuvering and slowing down on water. Pilots of multi-engined seaplanes can use differential reverse to make tight turns in water or pull out of docks.

Operational Use of Thrust Reversers

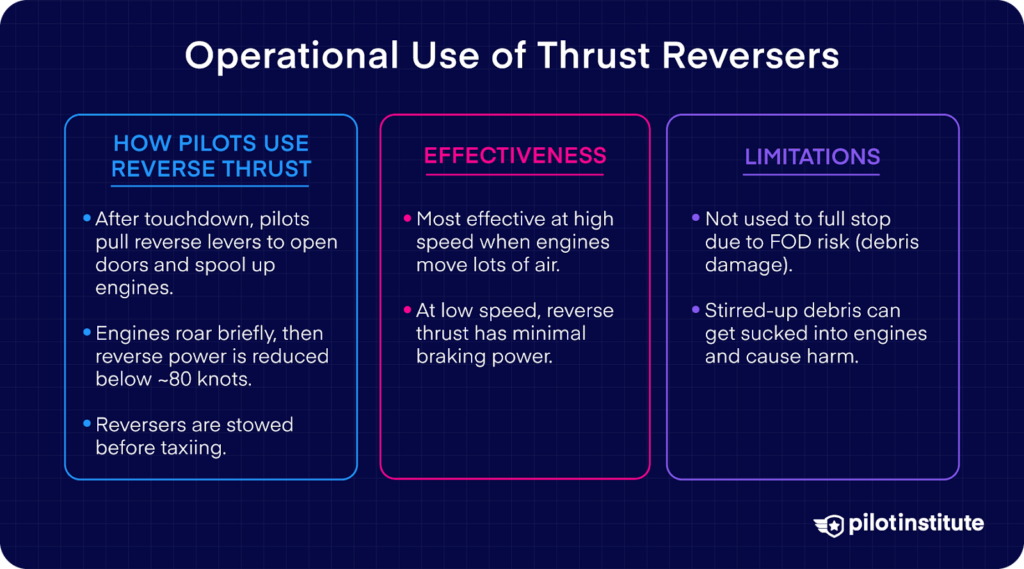

So, how do pilots engage reverse thrust?

- As the aircraft is on short final, the pilot typically moves the throttles all the way back to idle. The auto-brake system engages as soon as the main landing gear touches down and spins up to speed.

- At this point, the pilot deploys the thrust reversers.

In most aircraft, the throttle control levers have separate control levers to operate thrust reverse. When the throttle is idle, the pilot pulls the reverse thrust levers backward. This opens the reverser doors and spools the engines up as the pilot pulls them all the way back.

This explains why you hear the engines roar at touchdown as a passenger. - Pilots usually keep the engine at a high reverse thrust setting just for a few seconds. By the time the aircraft decelerates below roughly 80 knots, the pilot moves the reverser controls to the idle reverse position. The engines throttle back to idle at this setting, but the reversers stay deployed.

- Finally, the pilot moves the reverser levers back to the stowed position. This closes the doors again and returns the engines to normal forward idle. The rest of the taxi does not involve reverse thrust at all.

Effectiveness at Different Speeds

Since reverse thrust relies on engines alone, it is most effective when the engines are most effective.

Early in the landing roll, when the aircraft is still moving at high speed, the engines can gulp a lot of air even when idle. When spooled up to maximum reverse thrust, they can throw a huge mass of air forward, producing a strong braking force.

Why does the braking force reduce at low speeds?

At low groundspeeds, the air flowing through the engine is much less than at high speeds. This, of course, means less thrust. At extremely low speeds, let’s say taxi speeds, the reverse thrust is so low that it can’t really help with braking, even at high power.

Limitations and Considerations

Low effectiveness is just one reason pilots don’t use reverse thrust to bring the aircraft to a complete stop. Another major reason is the risk of FOD, which stands for Foreign Object Debris.

When you blast engine thrust forward, you inevitably throw whatever is on the runway forward as well. This can stir up sand, water, chunks of rubber from tires, or ice.

If that debris gets blown out front, there’s a chance the engines might suck it in from the front, especially as the aircraft slows and the relative wind drops. This can cause engine damage.

Safety and Performance Benefits

Reduced Brake Wear

Airliner brakes take a tremendous amount of stress during landing. They have to absorb and dissipate a lot of kinetic energy to slow the airplane down. If reverse thrust can offload some of that energy, the brakes can afford to work less hard.

This translates to less heat build-up in the brake pads and discs. It helps prevent scenarios like brake fade, where brakes lose effectiveness due to overheating, or even brake fires in extreme cases.

Even when brakes work perfectly fine, each landing does wear them out bit by bit.

Airliners often have high-tech carbon brakes that perform well but are expensive to replace. Airlines are always happy to save money by needing to replace them less frequently.

Reduced Landing Distances and Enhanced Safety Margins

In some cases, you need all the deceleration you can get. Reverse thrust can shorten landing distance by up to 20% compared to not using reverse at all.

If you are landing at close to maximum landing weight or if the runway is short, it might take the combined braking efforts of brakes and thrust reverse to bring the aircraft safely to a stop.

With that said, many landing distance calculations don’t take reverse thrust into account. That means they ensure the aircraft has enough runway available to stop, even if reverse thrust is unavailable due to engine failure.

This conservative approach means that you should always have more than enough room to land safely in all scenarios.

Case Studies and Examples

There are two main concerns when it comes to malfunctioning thrust reversers.

- One or more reversers could unlock and deploy uncommanded in mid-air.

- One of the engines could fail during landing while the thrust reversers are engaged.

Both scenarios can potentially be fatal.

In 1991, a Boeing 767 was operating Lauda Air Flight 004. Just after departure from Bangkok, its left thrust reverser unlocked with the engine operating at high thrust for the climb. The aircraft immediately lost control and crashed with total loss of life.

Aircraft usually have weight-on-wheel sensors that block thrust reverser deployment if not triggered. As a result of this incident, Boeing added a mechanical sync lock to the 767’s reversers as an extra precaution.

In the second scenario, the challenge is that a failure of one engine after touchdown would create so much asymmetric thrust that the aircraft would veer off the runway.

To counter this, the FAA recommends pilots don’t apply full reverse thrust until the nose gear touches down. This would give the pilots some way to steer against the asymmetric force and stay on the runway.

Advances in Thrust Reversal Technology

The earliest thrust reversers pioneered by the Boeing 707 used bucket-type reversers for good reason. Bucket-type reversers have the simplest actuation mechanism. They are very effective at blocking backward thrust while simultaneously redirecting it forward in one simple movement.

They did need lots of room below the engine to allow the big bucket door to swing backward, but that wasn’t much of a problem, given the small engines and ample clearance under the wing.

As engines improved over the years, they grew in diameter. Newer engines moved to high-bypass designs. Aircraft with tail-mounted engines, such as the DC-9, could get away with using buckets. Newer aircraft with wing-mounted engines had to find another way.

The cascade-type reversers took advantage of the thrust offered by the fan in high-bypass engines. Their sliding motion meant they could easily work with the limited clearance the large engines demanded.

Many Airbus aircraft, such as variants of the A320, A330, and A340 family, use small pivot-type doors that redirect cold-stream airflow.

Future Developments

With the push towards electric or hybrid-electric propulsion, reverse thrust could look very different.

An electric motor-driven propeller or fan can theoretically simply reverse its rotation or adjust its blade pitch to produce reverse thrust. That means there’d be no need for heavy doors or buckets. This could simplify engine designs for small electric aircraft or drones.

More conventional aircraft designs could keep using some type of cold-stream thrust reversers, with the only major innovations being advanced lightweight materials or some more efficient way to turn airflow around.

Conclusion

If you’re a passenger on an airliner, you can hear thrust reversers right after touchdown. If you’re watching the aircraft from the outside, you can see them deploy and retract through the landing roll.

Now you know just how important their role is and can appreciate their contribution to helping you slow down safely.