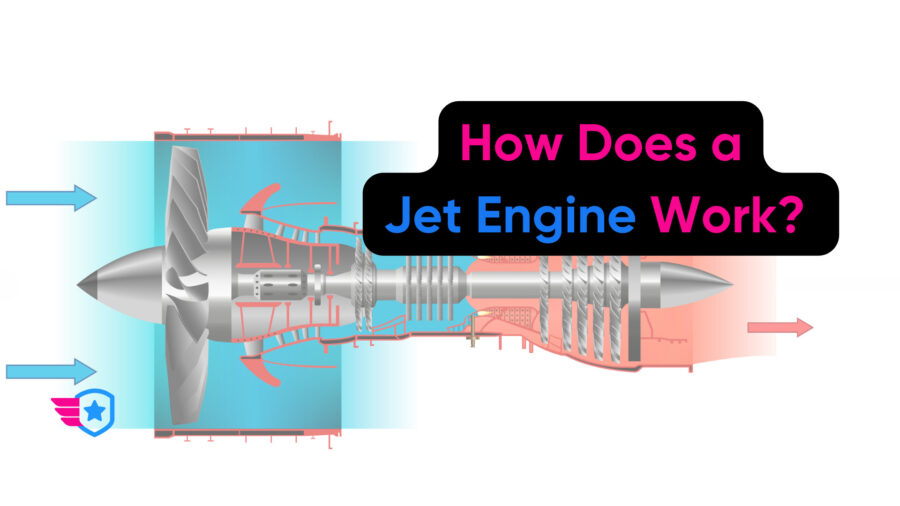

Jet engines are the powerhouses of aviation, but how do they work?

This article will cover the basics of how jet engines function and give you a peek into how they produce their immense power in various weather conditions.

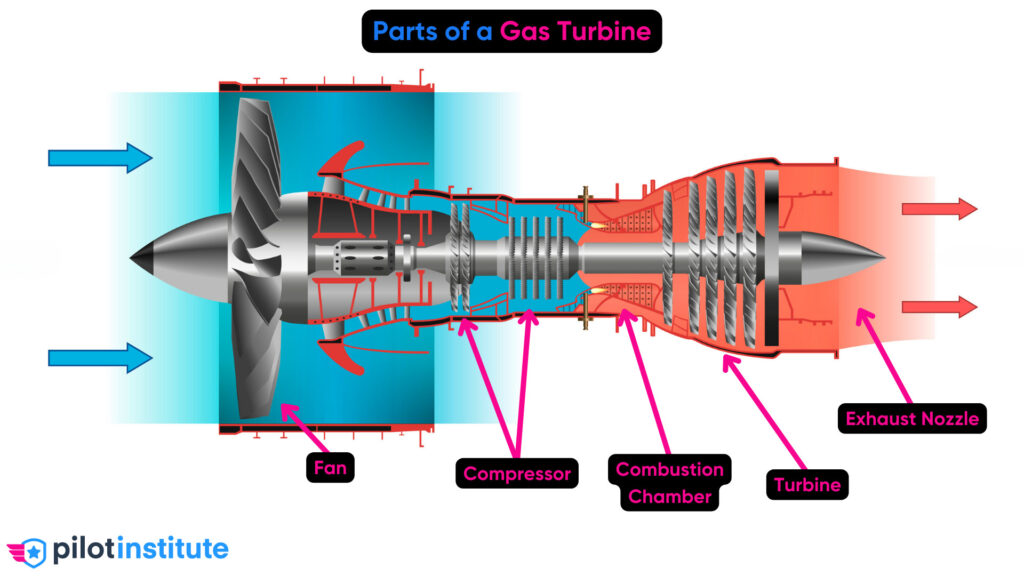

The Basics of a Jet Engine (Gas Turbine)

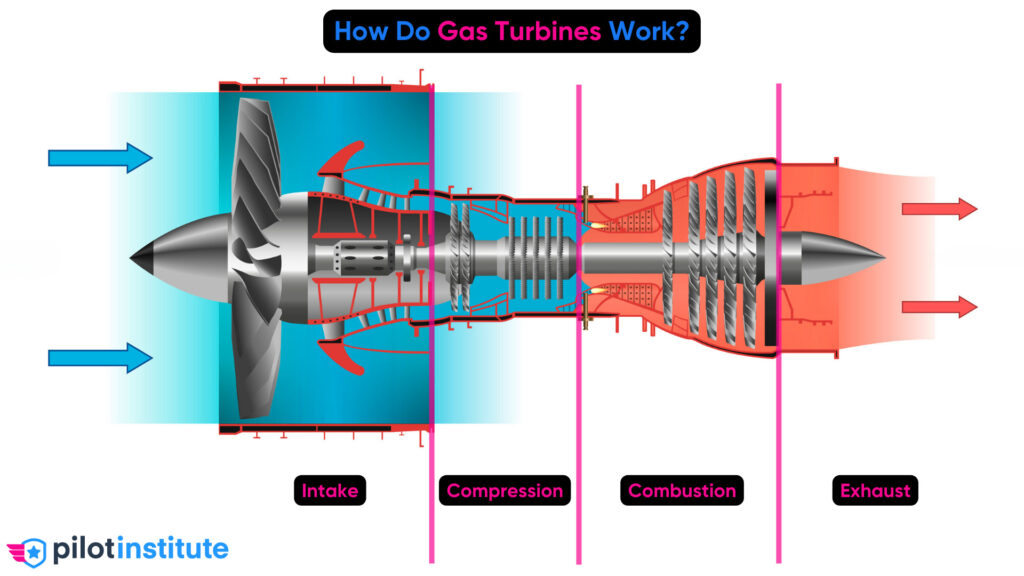

A gas turbine jet engine works by compressing air, mixing it with fuel, igniting the mixture, and ejecting the air behind the engine, creating a pushing force known as thrust.

The engine does this using the basic principle of intake, compression, combustion, and exhaust, known as the Brayton cycle.

This continuous cycle is what allows the engine to produce thrust. Let’s look at each part.

Step 1: Intake

Air enters the engine through an intake duct. This air is essential for the combustion process, and its speedy entrance is a crucial first step.

Step 2: Compression

This incoming air is squeezed into a compressor, raising its pressure and temperature. The compressed air then moves into the combustion chamber, setting the stage for the next step.

Step 3: Combustion

Here comes the combustion. Fuel injectors spray a fine mist of fuel into the compressed air in the combustion chamber. The mixture ignites, causing a dramatic increase in temperature and a rapid expansion of gases.

Step 4: Exhaust

Finally, exhaust. These hot gases rush out of the combustion chamber, passing through the turbine. The turbine, spun by this rush of gases, powers the compressor at the front of the engine. The remaining gases blast out of the back, propelling the aircraft forward.

Key Parts of a Jet Engine

Now that we understand the general idea of how a jet engine works, let’s dive into the components that make it happen – starting from the front.

Air Intake and Fan

This is where it all starts, the mouth of the engine. The air intake sucks in a large volume of air as the aircraft moves forward.

Joining the air intake in the spotlight is the fan. Sitting right behind the air intake, the fan is the first component to meet the incoming air in high-bypass turbofan engines, the type commonly used in commercial jet aircraft.

As the fan spins, it achieves two important things.

First, it pushes a large amount of air out around the sides of the engine, bypassing the core. This bypass air provides the majority of the engine’s thrust and makes the engine quieter and more fuel-efficient.

Second, the fan compresses a portion of the air and directs it into the engine’s core.

Compressor

This crucial component pressurizes the air taken in.

As air passes through the compressor, it moves across a series of rotating and stationary blades. Each stage of blades, spinning at high speeds, forces the air into a smaller and smaller space, compressing it more with each step.

By the time the air exits the compressor, its pressure can be many times higher than when it entered. The temperature has risen too, due to the pressure increase.

This hot, high-pressure air is now perfectly primed for the next stage of its journey: the combustion chamber.

Combustion Chamber and Fuel Injectors

Now that we’ve built up all this pressure with the compressor, let’s bring the heat!

Once the high-pressure air leaves the compressor, it enters the combustion chamber. Here, it’s about to go through a dramatic transformation.

In the combustion chamber, the air meets the fuel injectors. They spray a fine mist of fuel into the air, creating a highly combustible mixture. With a spark from the igniter, this mixture ignites, causing a mini explosion.

This combustion process massively increases the temperature and pressure of the air-fuel mixture. The hot, high-pressure gas expands and is ready to be expelled at high speed.

But there’s one more important step before that: the turbine.

Turbine

Remember how we said the combustion process creates a lot of energy? Well, the turbine is where we start to harness that power.

The hot, high-pressure gas hits the turbine blades, causing them to spin rapidly. This spinning motion does two crucial things.

First, it powers the compressor and fan at the front of the engine. They’re mechanically linked to the turbine, so when the turbine spins, so do they. This is how the turbine provides the power needed to suck in more air and keep the whole engine running.

Second, the spinning turbine also helps to expel the now lower-pressure gas out the back of the engine.

Exhaust Nozzle

The exhaust nozzle plays a vital role.

It’s designed to direct the expelled gas in a specific direction: straight back. This creates a strong force in the opposite direction, pushing the aircraft forward.

This is Newton’s third law in action: for every action, there’s an equal and opposite reaction.

The shape of the nozzle is key. It’s usually smaller at the end, which accelerates the gas as it leaves the engine, boosting the overall thrust.

Types of Jet Engines

The term “jet engine” doesn’t denote one type of engine. It’s an umbrella term encompassing several engine types, each with a unique operation and purpose.

While the general idea behind how a jet engine works is the same, there are many different types, such as the:

- Turbojet: Uses a series of compressor stages to ingest and compress air, which is then mixed with fuel, ignited, and expelled for high-speed propulsion.

- Turboprop: Uses a gas turbine to drive a propeller.

- Turboshaft: Generates power for a drive shaft, typically used in helicopters.

- Turbofan: Features a large fan at the front that draws in air, a portion of which bypasses the engine core. These are found on commercial jets.

- Turbofan with an afterburner: An extra component that introduces more fuel into the exhaust gases and ignites them.

These are traditional jet engines, known as “gas turbines.” They’re the ones that use the Brayton cycle discussed earlier.

You’ll also find other types of jet engines, such as the pulsejet, ramjet, or rocket. They’re all technically jet engines, but they aren’t gas turbines.

Conclusion

Whether you’re a seasoned aviation professional or just an enthusiast, having a firm grasp of how jet engines work can deepen your appreciation of every flight you take.

So the next time you hear the roar of jet engines as your airplane takes off, you’ll know precisely what’s happening inside these mechanical marvels!