-

Key Takeaways

-

How Flight Control Systems Work

- Traditional Mechanical and Hydraulic Controls

- The Evolution to Fly-by-Wire Technology

-

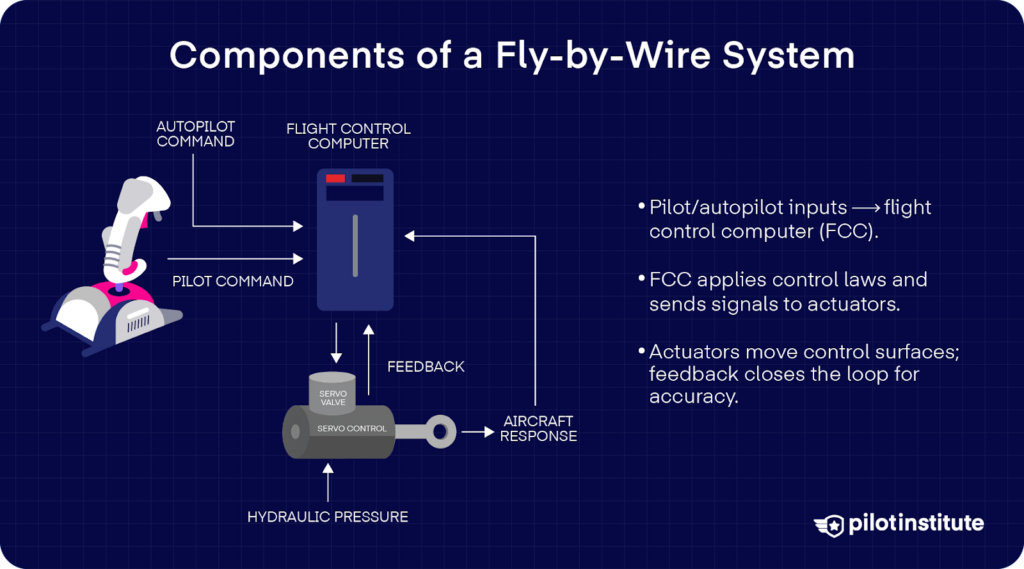

Components of a Fly-by-Wire System

- Pilot Input Devices

- Flight Control Computers (FCCs)

- Actuators and Control Surfaces

-

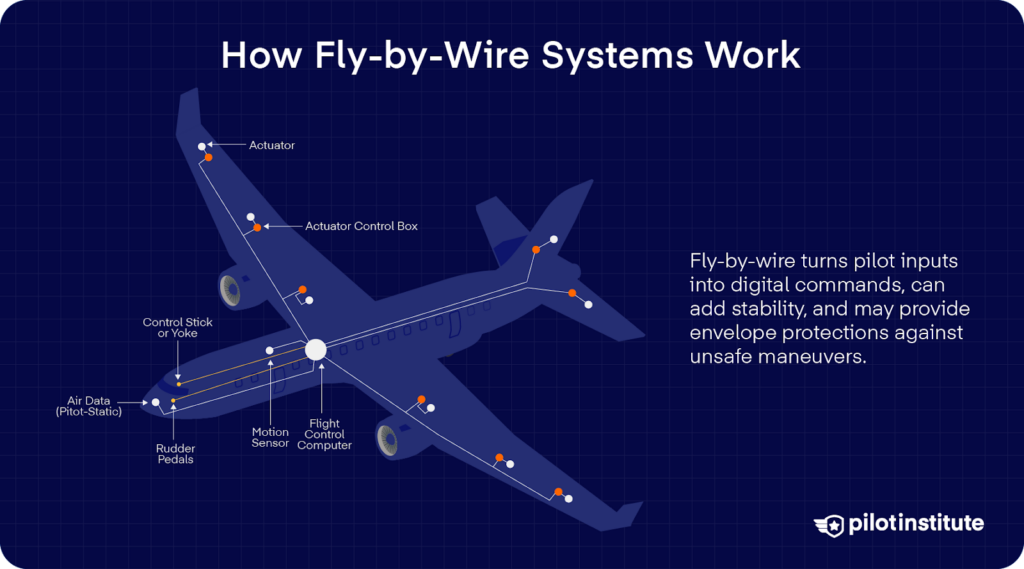

How Fly-by-Wire Systems Work

- Signal Processing and Control Laws

- Automatic Stability and Protection Features

-

Advantages of Fly-by-Wire Technology

- Weight Reduction and Structural Benefits

- Enhanced Aircraft Performance

- Increased Safety Measures

- Reduced Pilot Workload

-

Challenges and Considerations

- Loss of Tactile Feedback

- System Complexity and Reliability

- Training and Adaptation for Pilots

-

Fly-by-Wire in Practice

- Military Aircraft Applications

- Commercial Aircraft Implementations

- Differences in Manufacturer Philosophies

-

The Future of Fly-by-Wire Systems

- Advances in Fly-by-Light and Power-by-Wire

- Integration with Autonomous Systems

- Ongoing Developments in Safety and Efficiency

-

Conclusion

Imagine flying an aircraft where every input you make is instantly processed by sophisticated computers, where your every command gets optimized for peak performance and safety. In a fly-by-wire aircraft, you might feel like you’re flying in luxury.

Not that long ago, though, pilot inputs traveled through cables and rods that directly moved the control surfaces. But as aircraft grew and flew faster, those systems became heavy and impractical.

Nothing breeds innovation like a good challenge. And after years of trial and error, that bulky mechanical chain was replaced with electrical signals and computers.

They called this system fly-by-wire. It’s been one of the most significant evolutions in flight controls. In today’s aviation, it has enhanced safety and maneuverability.

So, how does it work? What are the pros and cons? And how did we get here? Let’s talk about it.

Key Takeaways

- Fly-by-wire replaces mechanical linkages with electronic signals, giving pilots precise and reliable aircraft control.

- It transmits pilot inputs through computers, which send electrical commands to control surfaces.

- These systems are lighter and safer, although they may be more complex and feel unfamiliar.

- Future systems may integrate fly-by-light, power-by-wire, and automation for safer, more efficient, and autonomous flight.

How Flight Control Systems Work

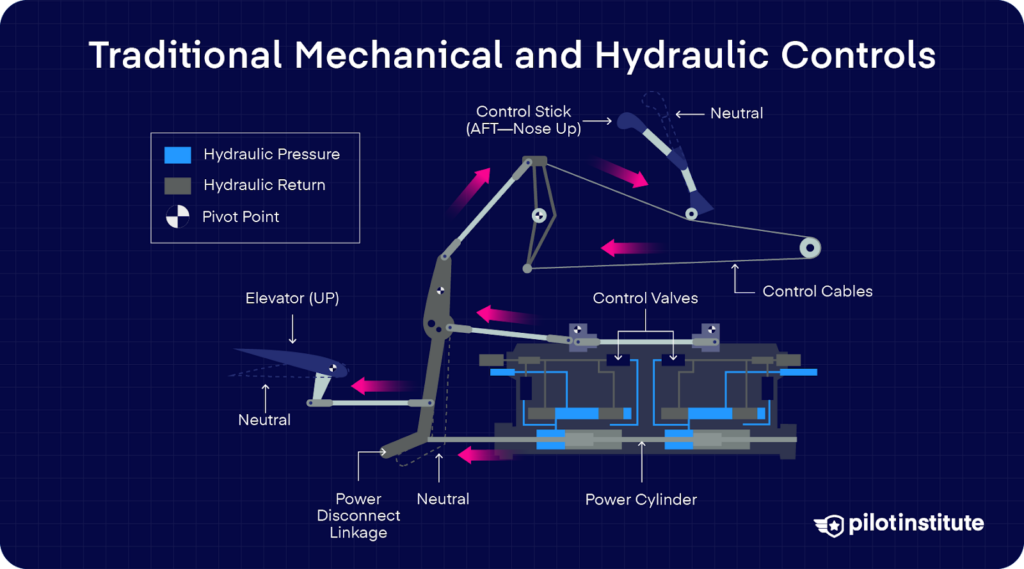

Traditional Mechanical and Hydraulic Controls

Flight controls relied on simple mechanical connections for much of aviation history. When you moved the yoke or rudder pedals, your input traveled through a system of cables, pulleys, rods, and sometimes hydraulics.

Pilots got a reassuring sense of connection with this setup. You could feel a tactile resistance and feedback from the aircraft itself. However, it didn’t come without some major drawbacks.

What were the downsides? First of all, the weight of all those linkages cuts into performance and fuel efficiency.

But aside from being bulky, they were so complex that they became more prone to wear. You can imagine the amount of maintenance it’ll take to keep all those parts working properly.

On top of that, engineers had to design stability into the airframe itself. As a result, the aircraft’s maneuverability became limited.

You’d have a hard time flying the aircraft in different flight conditions. If you’re flying a fighter, this would be a real concern.

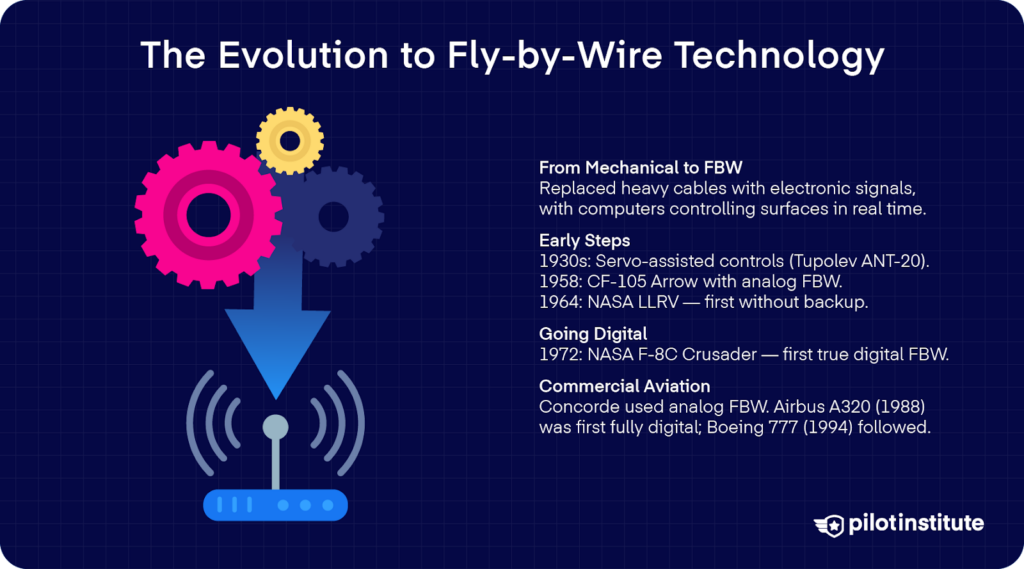

The Evolution to Fly-by-Wire Technology

The breakthrough came with the shift from mechanical flight controls to fly-by-wire (FBW). This is a system that replaces mechanical linkages with electrical signals.

Gone was the need for heavy cables and connectors. Instead, your control inputs can be converted into electronic signals, transmitted through wires, which are then processed by computers.

Those computers then command the actuators that move the control surfaces. In other words, your aircraft has a smart intermediary that will optimize your actions in real time.

Early Experiments

How did we get here? There were some important milestones along the road to digital control.

In the 1930s, the Soviet Tupolev ANT-20 and other similar aircraft experimented with servo-operated controls. In a way, this era kicked off the development of future fly-by-wire systems.

In 1958, the Avro Canada CF-105 Arrow became the first non-experimental aircraft to fly with an analog fly-by-wire system. It used electronic signals instead of cables and even had an artificial “feel” system for the pilot.

A few years later, in 1964, NASA’s Lunar Landing Research Vehicle (LLRV) took the concept even further. It was the first fly-by-wire flight without mechanical backup. It relied entirely on electronic control with redundant systems to simulate landing on the moon from here on Earth.

Going Digital

But the real turning point came in 1972, when NASA modified an F-8C Crusader. They removed its mechanical backups and flew it using an Apollo digital flight-control computer. This was the first true digital fly-by-wire system.

FBW in Commercial Aviation

Fly-by-wire made its way to commercial aviation not long after. Concorde came out with analog fly-by-wire, and in 1988, the Airbus A320 became the first airliner with a fully digital fly-by-wire system. Their approach was later adopted by Boeing in 1994 with the 777.

Components of a Fly-by-Wire System

Fly-by-wire simplified aircraft’s control systems into a cleaner, smarter design. It’s less complex yet more precise, all while electronics do the heavy lifting.

So, what’s in a fly-by-wire system? Let’s dissect and take a look.

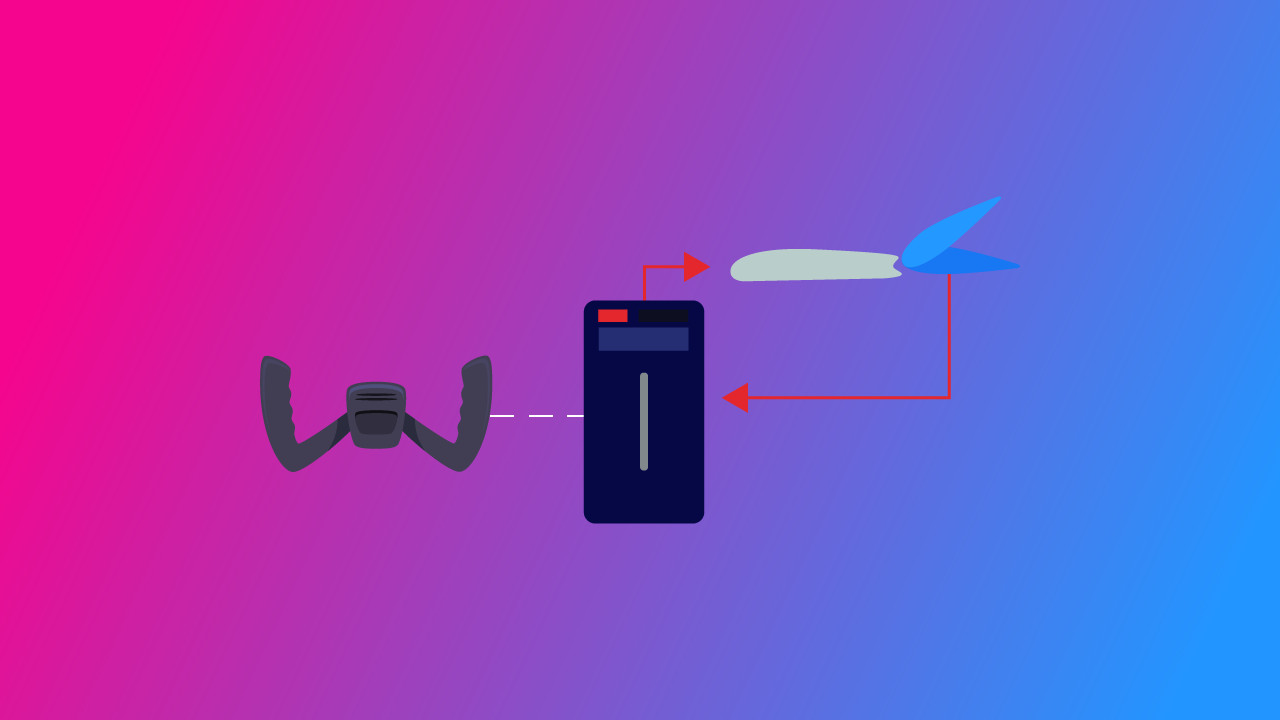

Pilot Input Devices

When you’re flying an Airbus with a sidestick or a Boeing equipped with a traditional yoke, your inputs begin the moment you move the control device. Alongside the rudder pedals and trim controls, your commands will have their starting point in these devices.

Sensors or transducers then convert your physical movements into electronic signals that feed into the fly-by-wire system.

As you can see, it doesn’t really matter which input device you’re comfortable with. They both blend seamlessly into the flight control system.

Flight Control Computers (FCCs)

Your input data then goes to the brain of the whole operation. We’re talking, of course, about the Flight Control Computers (FCCs).

These computers receive your signal along with other inputs. They also get data from a network of sensors, including airspeed, altitude, attitude, and more.

Then, they apply control laws, which determine how the aircraft should respond based on flight mode. What does this mean? To put it simply, control laws can be classified into three categories: Normal, Alternate, and Direct.

Control Laws

You’re flying under Normal Law when all systems are functioning. Full protections for issues like stall, overspeed, and bank-angle limits are active and running.

If multiple failures of redundant systems occur, then you’ll be flying under Alternate Law. So if—say—two air-data or inertial reference systems fail, or if you suffer faults in more than one flight control surface actuator, then you lose some of the protections that you’d get under Normal Law. The autopilot is often unavailable in these cases, and your workload piles up.

Under Direct Law, however, all of these protections are unavailable. Your inputs would essentially go straight to the control surfaces. Control sensitivity will depend on airspeed, and you wouldn’t have any autotrimming available, for example.

System Redundancy

How can you improve your odds from reaching this point? Fly-by-wire systems are designed to be much more reliable than old mechanical controls.

They’re triple- or even quadruple-redundant, which means multiple backup systems are always running. Even if one or two parts fail, the others keep working to keep your aircraft controllable.

Actuators and Control Surfaces

If the FCCs are the brains, then the actuators are the muscles of a fly-by-wire system. It’s these systems that translate electronic commands into physical movement.

Actuators carry out the actual work of moving control surfaces. These are your elevators, ailerons, and rudders. But did you know that actuators can also come in different forms?

Types of Actuators

First up are the hydraulic actuators. They’re the traditional choice. They use pressurized fluid to perform powerful and reliable movements. This is essential, especially in larger aircraft.

Modern designs often incorporate electrical actuators. They have the advantage of using electric motors, which cuts both weight and maintenance requirements.

Then you’ve got the hybrid option with the electro-hydraulic actuator. It’s got both the efficiency of electrical control and the strength of hydraulic power.

Feedback Mechanisms

How can we make sure that these machines are working as they should?

Actuators are equipped with feedback systems. They report the exact position of the control surfaces back to the flight computers.

It makes a closed loop that lets the system confirm that every movement matches the command sent.

How Fly-by-Wire Systems Work

Now that we know the basic parts of an FBW system, how do they all come together to control your aircraft? As each component does its job, they also work together to make sure your aircraft flies smoothly with you in control.

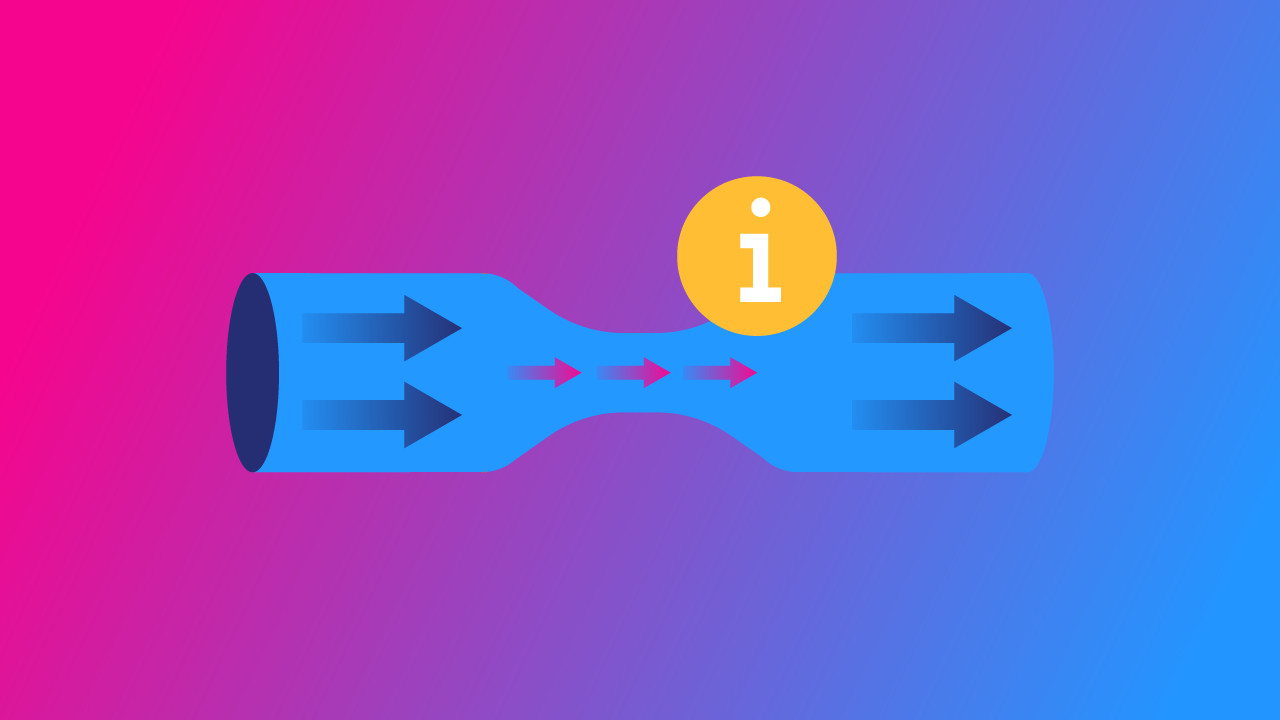

Signal Processing and Control Laws

When you move the control devices, your input becomes a digital command that travels to the Flight Control Computers.

These FCCs then interpret what you want to achieve, like a climb or turn. Then, they apply the control laws. Remember that these rules determine precisely how the aircraft should respond.

The feedback loop works to keep the control responses accurate behind the scenes. Sensors constantly monitor how your control surfaces move and compare that to what the FCCs intended.

So, what if the sensors detect an error or deviation? In normal conditions, the system simply corrects it in an instant.

That’s the great thing about having a closed-loop control. Your every maneuver matches your intention, but it’s also refined with precise adjustments.

Automatic Stability and Protection Features

One of the standout benefits of fly-by-wire is that the aircraft can look after itself. This, of course, comes with a bit of help from you.

Built-in flight envelope protections keep your aircraft going past aerodynamic or structural limits. They give you a layer of protection against stalls, overspeeds, excessive bank angles, or high load factors.

Angle-of-attack protection and load factor limitation nudge your inputs back into the safe zone. They actively prevent your aircraft from getting into dangerous flight regimes.

The interventions they make are subtle, but they are effective. They could even keep you from fully making an out-of-bounds maneuver.

There’s also auto-trim functionality that keeps the aircraft flying straight with minimal input from you.

For example, Airbus systems using Normal Law adjust the stabilizer automatically to relieve continuous pressure on the elevator.

Advantages of Fly-by-Wire Technology

Weight Reduction and Structural Benefits

One of the most immediate perks of fly-by-wire is simply shedding weight. Swapping out heavy mechanical linkages for lightweight electronic wiring and sensors immediately lightens your aircraft’s load.

What do you get from a lighter aircraft? Better fuel efficiency and a larger payload that it can haul. This frees up designers to push aircraft performance further.

There also wouldn’t be as much of a need to build in inherent aerodynamic stability. That means designers can create airframes with “relaxed static stability,” which does wonders for the maneuverability of fighter aircraft.

On top of that, reduced reliance on large control surfaces becomes possible, since the computers deliver higher precision control right where it’s needed.

Enhanced Aircraft Performance

Handling an aircraft equipped with fly-by-wire feels sharp, like your moves in the cockpit are more precise and immediate.

The system optimizes how control surfaces move. It reduces unnecessary drag and smoothens transitions through different phases of flight.

Plus, it’s constantly adapting anywhere you fly, no matter if you’re in calm or turbulent air.

Increased Safety Measures

Safety is built into every line of code and circuit in a fly-by-wire system. Computers are redundant and designs are tolerant to faults. If one component fails, another instantly takes over.

You also benefit from flight envelope protections. Even if your fingers tighten too much on the controls, the system won’t let things get unsafe.

You’ll be at less risk of pilot-induced oscillations or simple human error. Having oversight like that isn’t easy to find in a mechanical control system.

Reduced Pilot Workload

Fly-by-wire also takes many routine tasks off your hands. Auto-trim and envelope monitoring all run quietly in the background.

What does that give you? More space to think. Where you used to spend mental energy on constantly correcting or fighting load forces, you’ll now be able to focus on planning, decision-making, and managing the flight.

And even in big emergencies like a control surface failure, IFCS (Intelligent Flight Control Systems) have proven they can help you maintain control and complete safe landings. But aside from easing your workload, it also improves the mission capability of your aircraft.

Challenges and Considerations

But while fly-by-wire seems like the best way to go, it’s still got some downsides that you have to keep in mind if you don’t want to be caught off-guard.

Loss of Tactile Feedback

One of the big shifts with fly-by-wire systems is that you lose that customary physical feedback from the controls.

In traditional mechanical setups, the forces you feel from things like wind resistance or stall buffeting are all passed back through the controls. In essence, you get a sense of how the aircraft is behaving.

Much of that direct feedback is gone with fly-by-wire. What’s the alternative, then?

Designers came up with artificial “feel” systems to simulate control resistance. These are usually through springs or force feedback.

They were made to restore the sensory cues that you’d rely on for situational awareness. However, there is a subtle but undeniable change. They may not cue you as clearly when flight envelope limits are near in some cases.

System Complexity and Reliability

Fly-by-wire systems have some great capabilities, but they don’t come without their own complexity. Remember that you’re trusting computers and sensors to interpret and execute every command.

Yes, systems are typically designed with triplex- or quad-redundancy. Backup control laws are kept deliberately simple so that if the primary system fails, the fallback can still safely transition control.

And yet, the real challenge lies in managing complexity. It’s not easy to test for every potential failure. Historical incidents like software glitches or sensor corruption have taught us that even well-designed systems can fail in ways you might not expect.

Training and Adaptation for Pilots

If you’re used to the traditional mechanical controls, it might take you a while to get fully accustomed to flying fly-by-wire. More than just learning a few buttons, it’s going to take almost a complete shift in mindset.

You’ll have to unlearn reliance on tactile feedback. Instead, you must learn to interpret artificial cues and system failure behavior.

You need to have a deep understanding of the different control laws. How do they shape handling? What protections do they offer? You’ll need to master these things before you can be truly ready.

Keep in mind that to respect automation, you first must understand it. That understanding only comes through disciplined training.

Fly-by-Wire in Practice

Military Aircraft Applications

Fly-by-wire first took flight in the military. As you might remember, it was the F-16 Fighting Falcon that became the first production aircraft to use digital fly-by-wire.

It was designed to do away with traditional aerodynamic stability on purpose. This is a concept known as relaxed static stability. You get better maneuverability as a result.

More aircraft, such as the F/A-18 Hornet, Eurofighter Typhoon, and F-35 Lightning II, soon followed suit. They had similar systems that they were able to use even in the most extreme maneuvers.

Commercial Aircraft Implementations

Airbus led the change with the A320 in commercial aviation. This was the first airliner to fly with digital fly-by-wire and sidestick controls.

You could say that fly-by-wire has shaped Airbus’s cockpit philosophy ever since. They carried this philosophy through the A330, A340, A350, and A380. These aircraft all shared the same envelope protection logic.

On the other side, Boeing created fly-by-wire with models like the 777 and 787. What you might notice, though, is that they kept the traditional yoke controls cross-linked between the left and right seats.

Differences in Manufacturer Philosophies

So, what are the main differences that set these two jets apart? Where Airbus and Boeing diverge in their philosophies comes down particularly in how they handle control limits and aircraft “feel.”

Airbus uses hard limits. The system interprets your inputs as flight path demands, and it prevents the airplane from exceeding its protected envelope. It effectively prioritizes automation over pilot authority.

Boeing, however, designs with soft limits. Take the 777; protections like stall or overspeed awareness are still available, but you can override them if needed.

Boeing also keeps the traditional tactile cues, such as having to re-trim with speed changes. You get computerized assistance, but there’s also that familiar handling quality.

The Future of Fly-by-Wire Systems

Curious to see what the future holds for fly-by-wire? Let’s turn our view towards the innovations on the horizon and how they might change the way you fly.

Advances in Fly-by-Light and Power-by-Wire

Emerging technologies in flight control are pushing things further than ever before.

For instance, Fly-by-Light swaps traditional copper wiring for fiber-optic cables. This gives the fly-by-wire system immunity from electromagnetic interference, on top of having a much larger bandwidth and less weight.

The Japanese Kawasaki P-1 maritime patrol aircraft is the first operational aircraft in the world to use a fly-by-optics system for flight controls.

Engineers are also looking into power-by-wire, which replaces hydraulic systems with fully electric systems. Without the heavy hydraulic plumbing, you’d get the benefits of lighter weight and simpler maintenance.

Integration with Autonomous Systems

But fly-by-wire isn’t just for manned flight anymore. These days, it’s making its way to unmanned and remotely piloted aircraft (UAVs). These aircraft are agile and precise, which are essential for advanced autonomy.

This sets the stage for single-pilot operations or even fully autonomous commercial flights. Of course, with that comes a host of ethical, regulatory, and safety considerations.

How can we deal with certification and public acceptance as you step back from the cockpit? This is one of the questions future aviation will have to reckon with.

Ongoing Developments in Safety and Efficiency

The sky’s the limit when it comes to enhancing safety and efficiency. One interesting research area is adaptive flight control systems.

NASA’s Intelligent Flight Control System (IFCS) uses neural network technology to adapt mid-flight. The system learns the aircraft’s behavior in real time and, if a control surface fails or is damaged, it can compensate to keep you flying safely.

Artificial intelligence and machine learning are also being applied for predictive maintenance and decision support. As advanced avionics integrate deeper into cockpit systems, the workload shifts from reactive to predictive.

You might soon be flying a smarter and safer aircraft that can stay ahead of issues before they arise.

Conclusion

Fly-by-wire technology has revolutionized aviation. It was able to replace traditional linkages with precise electronic systems, thus transforming how aircraft are controlled.

It lessened weight, improved performance, enhanced safety, and reduced pilot workload. For today’s pilots, we must understand it as part of adapting to the future of flight.

You have a duty to create a safer, more efficient, and more capable aviation industry. Staying trained prepares you to harness these new advancements.

How can you do your part to keep aviation aligned with both safety and innovation? This is now the question you must ask yourself. The work has only just begun.