Flaps are certainly not the flashiest part of an aircraft, but you need them in every takeoff and landing. Flaps help pilots increase lift and maintain a slower, more controlled flight.

But not all flaps are created equal, each type offers unique advantages (and trade-offs) when it comes to things such as performance, drag, and complexity.

In this article, we’ll break down the five main types of flaps: plain, split, slotted, Fowler, and slotted Fowler. Stick around to learn how they work and why they matter.

Key Takeaways

- Flaps increase lift at slower speeds by changing wing shape and surface area.

- Plain and split flaps are simple but create more drag.

- Slotted and Fowler flaps improve airflow and lift with less drag.

- Slotted Fowler flaps combine both features for maximum performance.

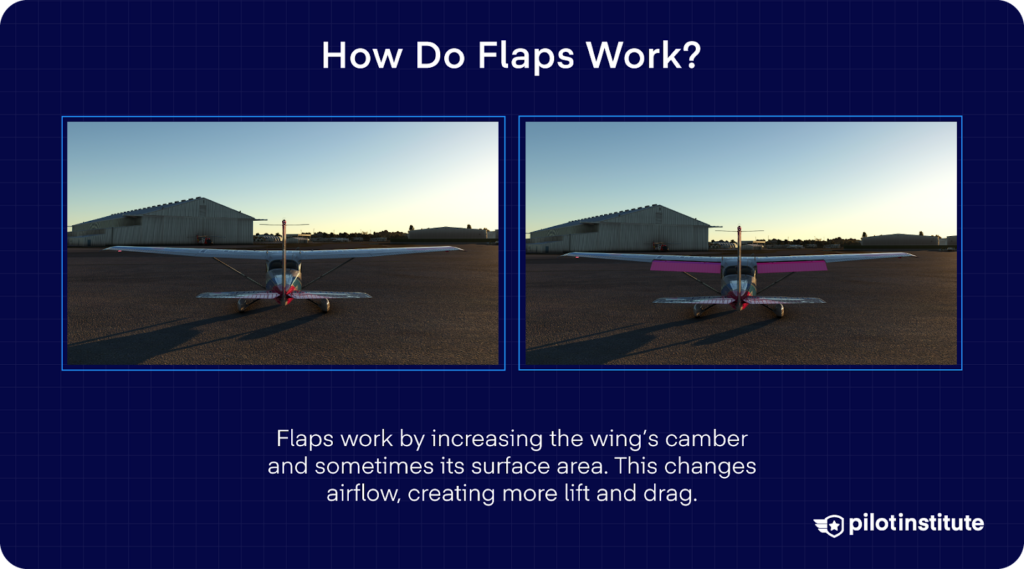

How Do Flaps Work?

Flaps are all about controlling airflow and increasing lift.

But how exactly do they do this?

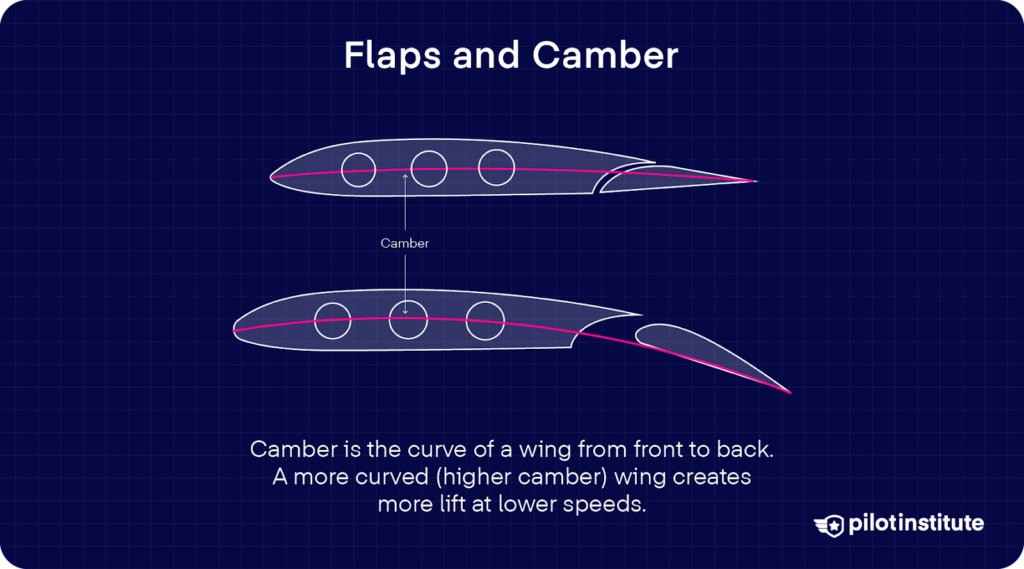

Well, it’s really all in the shape of the wing. The wing’s camber, or curve, becomes more pronounced, increasing lift. With the extension of certain types of flaps, the wing’s surface area also increases, generating even more lift.

But wait, there’s more!

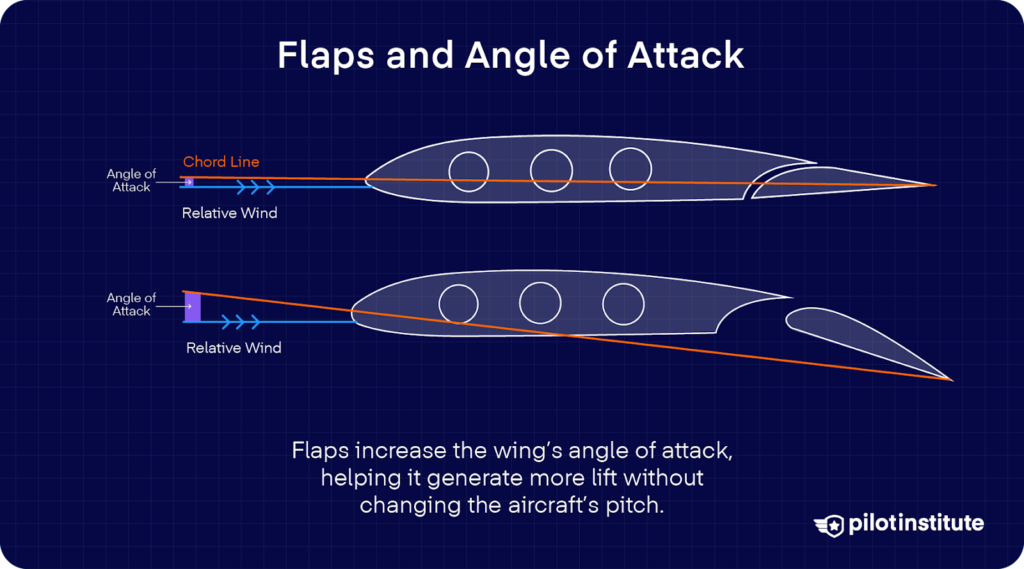

The deployment of flaps also results in a higher Angle of Attack, the angle at which air meets the wing. By increasing this angle, flaps create more lift. This helps enable the aircraft to maintain flight at slower speeds.

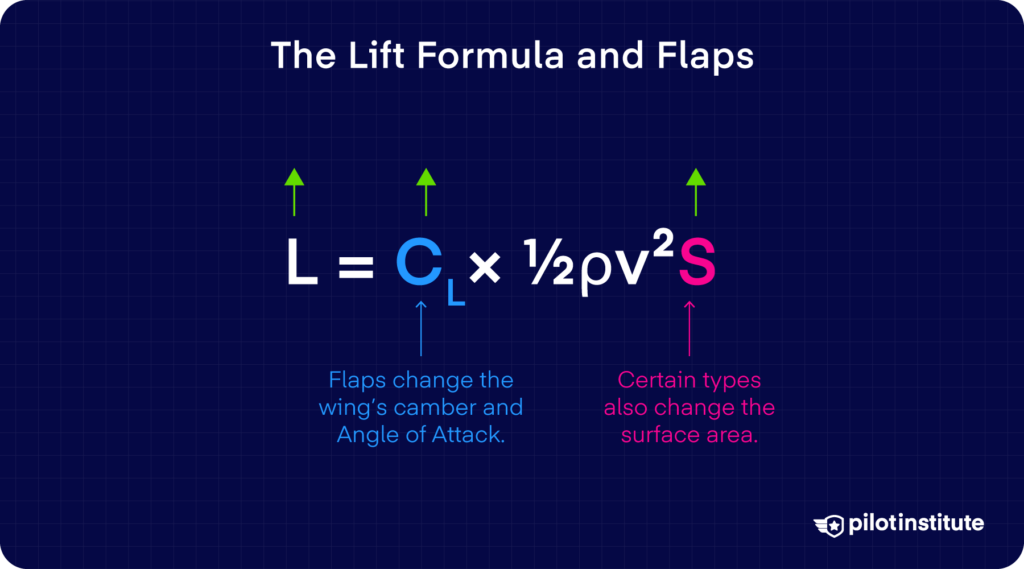

So flaps increase lift by changing three aspects (all found in the lift formula):

Camber (Coefficient of Lift)

Angle of Attack (Coefficient of Lift)

Surface Area (Only certain types of flaps.)

Remember, flaps are not just intended to be used for landings. You can utilize them for takeoff, too, especially when the runway is short. Since flaps help to increase lift, the aircraft can rise into the sky faster, making that short runway a non-issue.

In a nutshell, flaps allow us to generate more lift at lower speeds.

But for all of the previous reasons that flaps increase lift, they also increase drag. We can compensate for this increase in drag by increasing thrust.

We recommend checking out our video on How Lift Works.

Types of Flaps

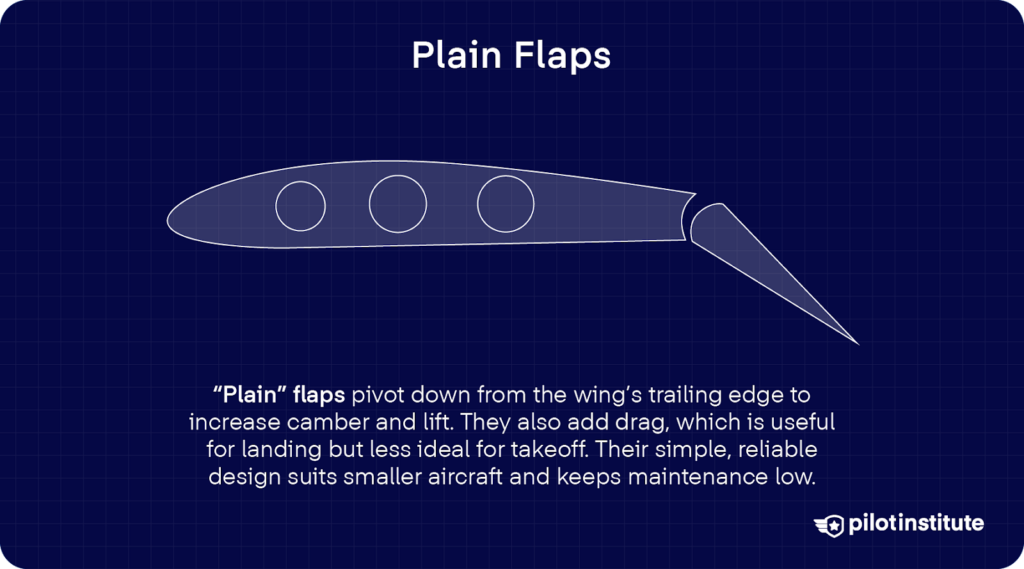

1. Plain Flaps

First on our list are the plain flaps. These are the simplest type of flaps in terms of design, which is why they have the name “plain.”

Flaps extend from the trailing edge of the wing and pivot downward when deployed, increasing the wing’s camber.

But there are some drawbacks to this type of flap. While plain flaps do a fine job of increasing lift, they also produce drag. This drag isn’t always a bad thing, particularly when you’re trying to reduce speed for landing. But during takeoff, it could make your aircraft work harder to get into the air.

Despite this, plain flaps have their advantages. They’re mechanically straightforward and reliable, making them a favorite for smaller, less complex aircraft. Their simplicity also means less maintenance, which is music to any pilot’s ears.

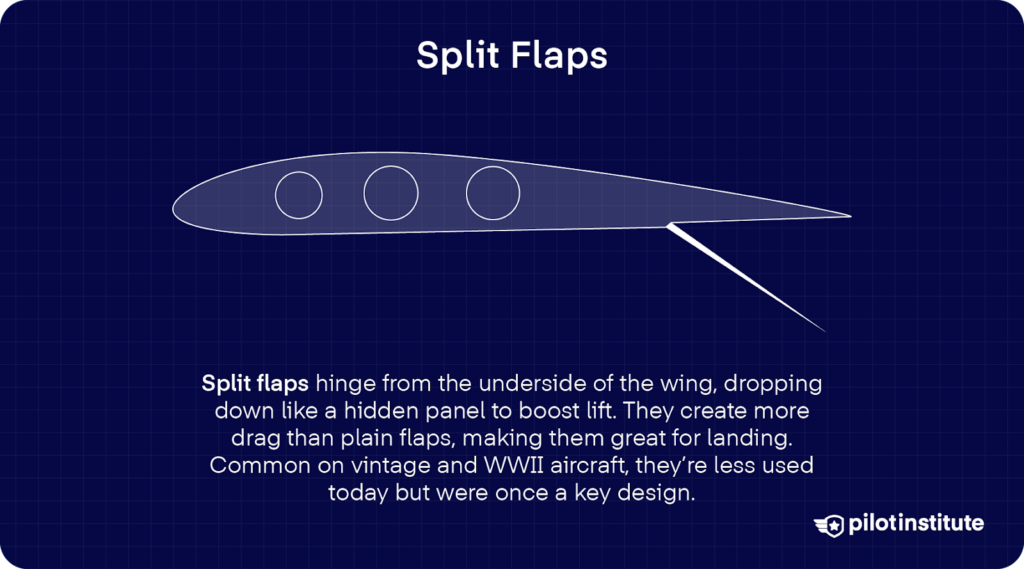

2. Split Flaps

Let’s move on to the next item on our aviation menu: the split flaps.

Now, these flaps are pretty interesting. They’re attached to the underside of the wing, and when deployed, they drop down from the wing’s trailing edge. This action, you guessed it, increases the wing’s lift.

Think about it like this: it’s as if the wing has a secret compartment that opens downwards. When this hidden door swings open (the split flap being deployed), it creates an abrupt, high-drag airfoil shape, enhancing lift generation but also producing significant drag.

Split flaps are considered more efficient at generating additional lift compared to plain flaps. However, they do produce a considerable amount of drag, even more so than their plain counterparts.

Where would you find split flaps? They’re commonly seen on vintage or older aircraft. While not as prevalent in newer models, split flaps hold an important place in aviation history, having served in many World War II airplanes.

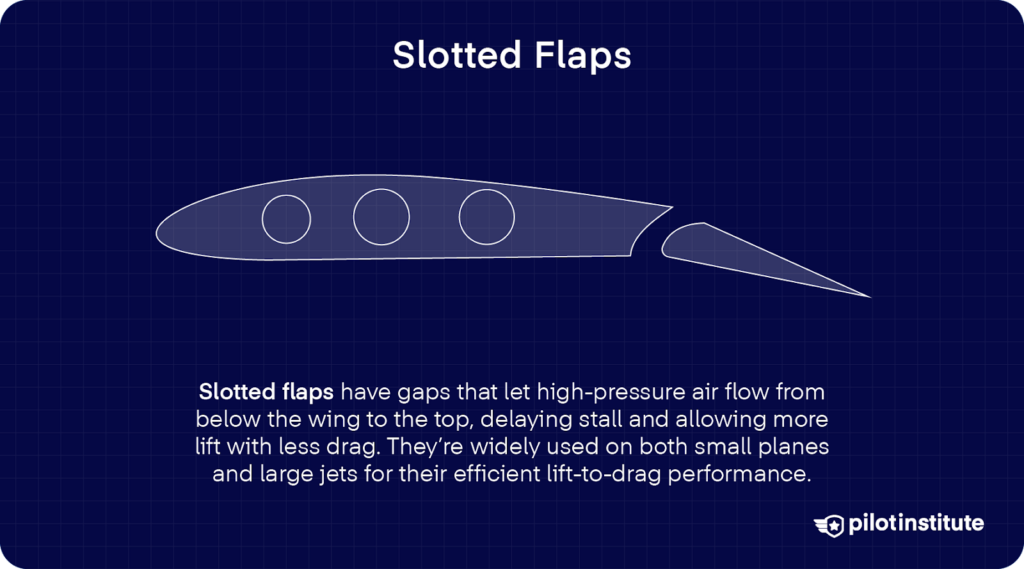

3. Slotted Flaps

Our aviation journey now brings us to the slotted flaps. These are an ingenious design upgrade over plain and split flaps, offering a brilliant solution to the high drag problem.

How do they work? Let’s find out.

Slotted flaps, as the name suggests, have one or more slots or gaps that allow high-pressure air from the underside of the wing to pass through to the top when the flaps are extended.

This nifty feature delays the airflow separation that leads to stall, allowing for a higher angle of attack and hence more lift, all without creating excessive drag.

Slotted flaps have proven themselves as game-changers in aviation. They’re a common feature on many types of aircraft, from small general aviation airplanes to larger commercial jets, thanks to their efficient lift-to-drag ratio.

They provide the best of both worlds: substantial lift without too much drag.

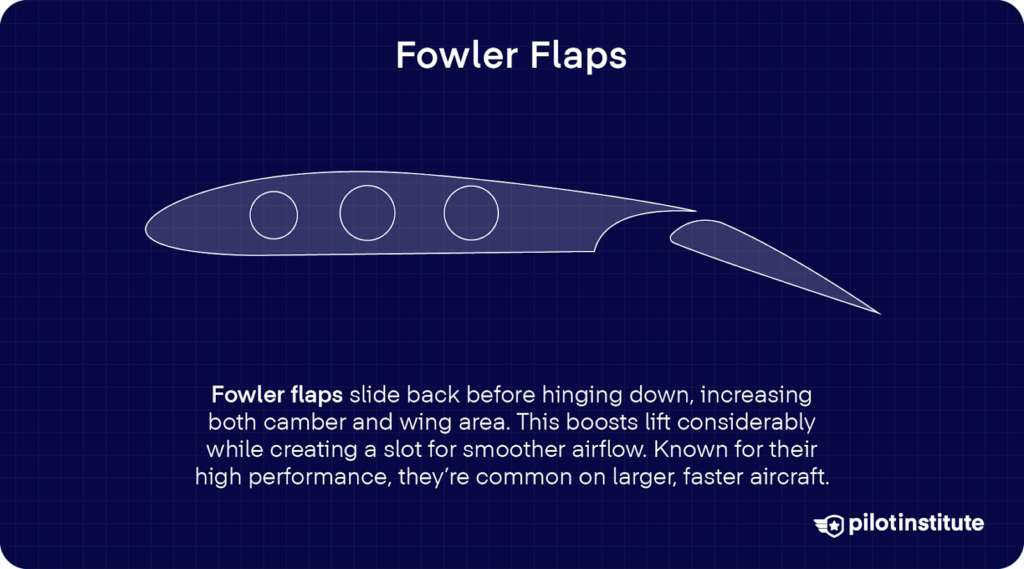

4. Fowler Flaps

Known for their intricate design and superior functionality, Fowler flaps are a favorite among many pilots, especially those flying high-performance aircraft.

So, what sets Fowler flaps apart?

When deployed, these flaps slide backward on tracks or rails before hinging downwards. This action not only increases the wing’s camber, like our previous flap types, but it also extends the wing’s surface area.

This increase in surface area, coupled with a more pronounced camber, leads to a significant lift increase.

But that’s not all.

The rearward movement of Fowler flaps also creates a slot, similar to slotted flaps. This slot allows for smoother airflow and higher lift generation at steeper angles of attack, without an excessive drag penalty.

Fowler flaps truly are the masters of lift and control, which is why you’ll often find them on larger, faster aircraft. Their ability to dramatically increase lift while maintaining a favorable lift-to-drag ratio is an invaluable asset during takeoffs and landings.

5. Slotted Fowler Flaps

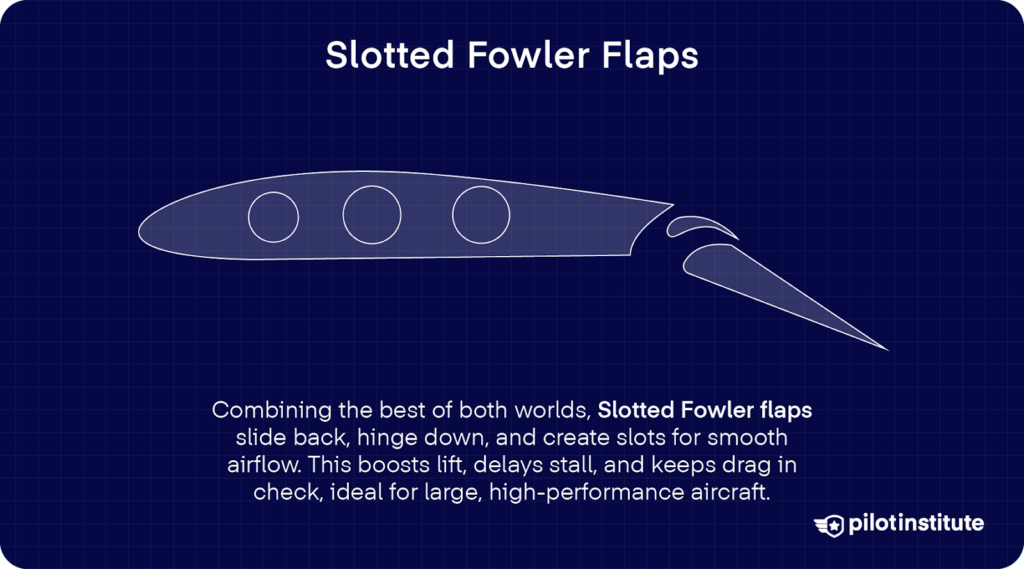

Just when you thought we’d covered all the flap types, we pull another one out of the bag: the slotted Fowler Flaps.

Think of these as the best of both the slotted and Fowler worlds. They bring together the increased wing area and lift of Fowler flaps with the smooth, efficient airflow of slotted flaps.

Slotted Fowler flaps slide backward and then hinge downwards when deployed, much like standard Fowler flaps.

The magic happens in the series of slots created in this process, which enables high-pressure air from beneath the wing to move to the top. This results in better lift and stall characteristics, particularly beneficial at low speeds during takeoff and landing.

It’s like your wing has an array of secret passageways, allowing the air to flow smoothly across the surface, preventing it from stalling at higher angles of attack.

The outcome?

Higher lift with manageable drag, giving you the best possible performance during those crucial takeoff and landing phases.

Due to their intricate design and superior performance, slotted Fowler flaps are often found on larger, commercial aircraft. Their combined benefits of increased lift, better stall characteristics, and efficient drag make them a worthy addition to any high-performance aircraft.

Conclusion

As we wrap up our journey through the land of flaps, it’s clear that these engineering marvels are far from simple. From the straightforward design of plain flaps to the intricate functionality of slotted Fowler flaps, each type is important for an aircraft’s performance.

Remember, understanding how each flap type works is key to maximizing its utility. Think about this if you’re taking off from a short runway or preparing for a smooth landing, flaps are there for you.

We hope this dive into the different types of flaps has given you a newfound appreciation for the complexity hidden beneath those wings. Keep these lessons in mind as you navigate your journey in aviation.

Fly safe, and remember, there’s always more to learn in the ever-amazing world of flight!